The influence of Automobile Wire Harness Design on Automobile Safety

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

Introduction

The automotive electronic system is an indispensable facility for the overall composition of the automobile, and the wire harness is the core component of the automotive electronic system.

The wire harness is responsible for the transportation of electric current and electrical signals. Wire harness is generally composed of plug wires, sensors, wires and other parts.

With the continuous vigilance of safety accidents, people have higher and higher requirements for automobile safety index. In order to meet the above requirements, we must rely on the safety of electronic technology.

In modern society, there are more and more electronic devices on cars, which not only meet people’s rich needs of life, but also make the circuits of cars become complex, resulting in the decline of the safety index of cars. The problem of automobile wire harness design is attracting people’s attention, and it is also a professional problem that must be solved.

Automobile wire harness and detection system

As the main part of automobile circuit network control, automobile wire harness plays an important role in all aspects of automobile performance.

If there is no guarantee of the safety of the car wire harness, then there will be no car safety.

In recent years, with the increasing requirements of automobile users for the safety, stability and comfort of the vehicle, the wire harness structure that makes up the automobile line becomes more and more complex. The automobile wire harness is mainly composed of the connection terminal by crimping copper wire material, then insulated and plastic sealed, and then bundled with the ties or parts to form the corresponding electrical components.

At the same time, the detection of automobile wire harness is also very important.

At present, the wire harness monitoring devices produced in China mainly use indicator lights, buzzer and so on, as the most basic electrical components.

Make a certain judgment on the normal operation of the line by detecting whether there is light or sound in the connection.

However, the use of this detection method has many disadvantages, low detection efficiency and high error judgment, which is very easy to cause wrong judgment and lead to the occurrence of automobile safety accidents.

Although the foreign wire harness detection system has been very mature, but its price is high, it is very difficult for some small wire harness manufacturers to purchase their equipment.

On the one hand, China still has to continue to make efforts to ensure the safety of the wire harness to the maximum extent, while producing domestic testing devices with high performance-to-price ratio.

Causes of wire harness ablation

The safety of the wire harness is very important for the automobile in the driving process, and the ablation damage of the wire harness mainly has the following aspects.

1. Line overload

Overload refers to exceeding the bearing range of the wire harness.

The main situation is the overload of the circuit or electronic components, which exceeds the fixed amount, resulting in excessive current in the wire harness, resulting in the overheating of electrical components.

The long-term use of electrical circuits will reduce the service life of electrical components, so it is necessary to regularly overhaul and maintain the circuits of electrical components in order to ensure the safety of automobile lines.

2. Line short circuit

Short circuit is very dangerous in electronic components.

A short circuit means that the current cannot flow through the whole circuit and the circuit will be closed within a range, which is equivalent to directly connecting the two poles of the battery.

A short circuit is fatal to an electronic system.

Because in the process of short circuit, the current will be very large and concentrated on a certain electronic component, then the temperature of the electronic component will rise, and when it exceeds the limit that the electronic component can bear, it is very likely to cause the burning of the electronic components and then cause the spontaneous combustion of the car.

Therefore, it is very important for regular inspection and maintenance of the line.

3. The relationship between fuse and circuit

Fuse plays a very important protective role in electronic components.

The selection of fuses should be matched with the circuit, and the position of the fuse should be placed reasonably, so as to protect the circuit effectively.

4. Selection of connectors

The connector between the circuits in the electronic components is also an important part.

The choice of connector is very important for electronic components, and the appropriate connector can better ensure its normal operation.

The selection of the connector should pay attention to its material, the current-carrying capacity of the terminal and its sealing properties.

Ground design of wire harness

Grounding is a prerequisite for the normal operation of the automobile internal circuit and the on-board electronic system.

The quality of the grounding has a significant impact on the automotive electronic system, affecting the electromagnetic compatibility of the vehicle.

A good grounding environment not only plays an effective role in balancing the battery volume of the vehicle, but also can effectively restrain the electromagnetic interference and the tolerance of anti-interference ability.

The grounding technology in wire harness design is very important for the electronic system of the whole vehicle.

In order to ensure the normal operation of the electronic system, it is necessary to make a reasonable design and analysis according to its functions, attributes and characteristics.

For example, it is necessary to ground in a separate environment for some current-sensitive electronic components, sensors and so on.

Control parts also need to ground in different ways, so as to avoid the interference between different signals.

In the process of grounding for generators, transmissions and other important driving components, it should be carefully designed to ensure the stability of the driving environment.

The arrangement of the grounding points on the car body should not be too dense, and a certain distance should be maintained to avoid burning the lines caused by the aging of the insulation.

Reliability of automobile wire harness system

Reliability is a new scientific discipline in recent years, which always runs through all the technical fields.

The safety of automobile wire harness design is very important for the whole automobile electronic system.

The reliability of wire harness design is an embodiment of security.

The following states the reliability points of view of wire harness design.

1.Reliability of terminals and connectors

As an important part of the automobile wire harness, line terminals and connectors are the main components that determine the reliability of the wire harness system, and play a vital role in the line system.

Terminals and connectors account for a large part of the many problems that occur in the wire harness.

For example, the aging of terminals, the shedding, loosening, damage of connector components.

These problems may be a small detail in ordinary times, but if they are placed in the whole wire harness safety system, it will lead to the reduction of the safety and reliability.

Therefore, in the usual wire harness design, some measures should be taken to ensure the reliability of wire harness design.

For example, in the process of installation,

①.select the appropriate connector and terminals, etc.;

②.pay attention to their material problems;

③.pay attention to the working environment, temperature and maximum current of terminals and connectors;

④.avoid some corrosive gases or liquids affecting the terminals and connectors, thus destroying the reliability of the entire electronic system.

2.Reliability of wire harness protection

The working environment of automobile wiring harness is very bad, which is often accompanied by corrosive gas and liquid, as well as high temperature, humidity and collision and friction with other parts, and problems such as damage of insulator coat and loose interface often occur. As a result, the wiring of the harness is short-circuited or broken, affecting the overall electronic system.

Therefore, in order to improve the safety of automobile wire harness design, we must make a good work plan of wire harness design and bandage and fix the wire harness effectively.

The design of automobile wire harness should have measures such as moistureproof, anticorrosion and high temperature, and at the same time ensure that it has good air-tight materials to protect joints and connectors.

When installing the wire harness in other parts of the car body, professional straps and wire clamps should be used to fix it, so as to reduce the impact of vibration on the car wire harness during driving.

At the same time, for some connection positions, it is necessary to do a good job of protection, in order to avoid the friction between the wire control and the wire harness, which leads to the wear of the insulation coat.

In the packaging, it is necessary to analyze the different working environments of different parts to characterize their service life and reliability.

It is necessary to carry out a variety of comparative tests of materials, and then select the appropriate materials.

It is also necessary to test the reliability of the wire harness in the harsh environment to avoid the flow of non-conforming products into the next link.

3.Reliability of circuit design

The design of automobile wire harness system is a very complex project, especially the current circuit problem of the line.

From some specific environmental conditions, the reasonable design of the circuit is the core of the electrical system.

In general, the automobile circuit system is connected in parallel in different electronic devices.

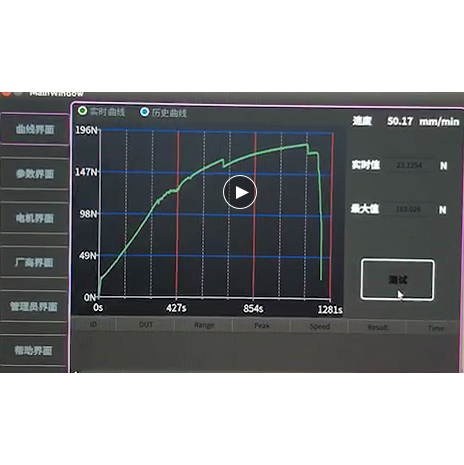

In order to test its line, it is necessary to change the connection mode of the line and simulate what may happen under various circumstances, so as to ensure the normal operation of the wire harness system.

Conclusion

With the rapid development of automobile industry and electronic technology industry, the use of electronic technology in automobile is becoming more and more common, and users’ requirements for all aspects of automobile are increasing.

In addition to its own functionality, a lot of entertainment and security measures have been added.

However, the body space of the car is limited.

So the design of the wiring harness of the car line is very important.

The improvement of the reliability of automobile wiring harness design is a tedious industrial test process, which must have omni-directional control over all aspects of automobile wiring harness system design.

The wire harness design of the car is not only of great significance for the safety of the car itself, but also plays a vital role in the safety of people who trust this product and people in driving.