8 advantages of terminal crimping in wiring harness

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

Terminal crimping in wiring harnesses offers several advantages that contribute to the overall quality and reliability of electrical connections. Let’s explore these advantages in detail.

1. Secure and Reliable Connections

Terminal crimping ensures a secure and reliable electrical connection between wires and terminals. The crimping process creates a mechanical bond between the wire and terminal, preventing accidental disconnections due to vibrations, temperature changes, or other external factors. This reliability is crucial in various industries, including automotive, aerospace, and electronics, where safety and performance are paramount.

2. Enhanced Electrical Performance

Crimping terminals onto wires provides excellent electrical conductivity. The crimping process creates a low-resistance connection, minimizing voltage drops and power losses. This is particularly important in high-current applications, where even small resistance variations can impact performance. Terminal crimping ensures consistent and efficient power transmission, resulting in improved electrical performance.

3. Cost-Effective Solution

Terminal crimping offers a cost-effective solution compared to other methods like soldering or welding. Crimping eliminates the need for additional materials such as solder or flux, reducing material costs. Moreover, crimping is a faster process, requiring less labor time compared to soldering or welding. This efficiency translates into cost savings, making terminal crimping an attractive option for mass production and large-scale manufacturing.

4. Versatility and Compatibility

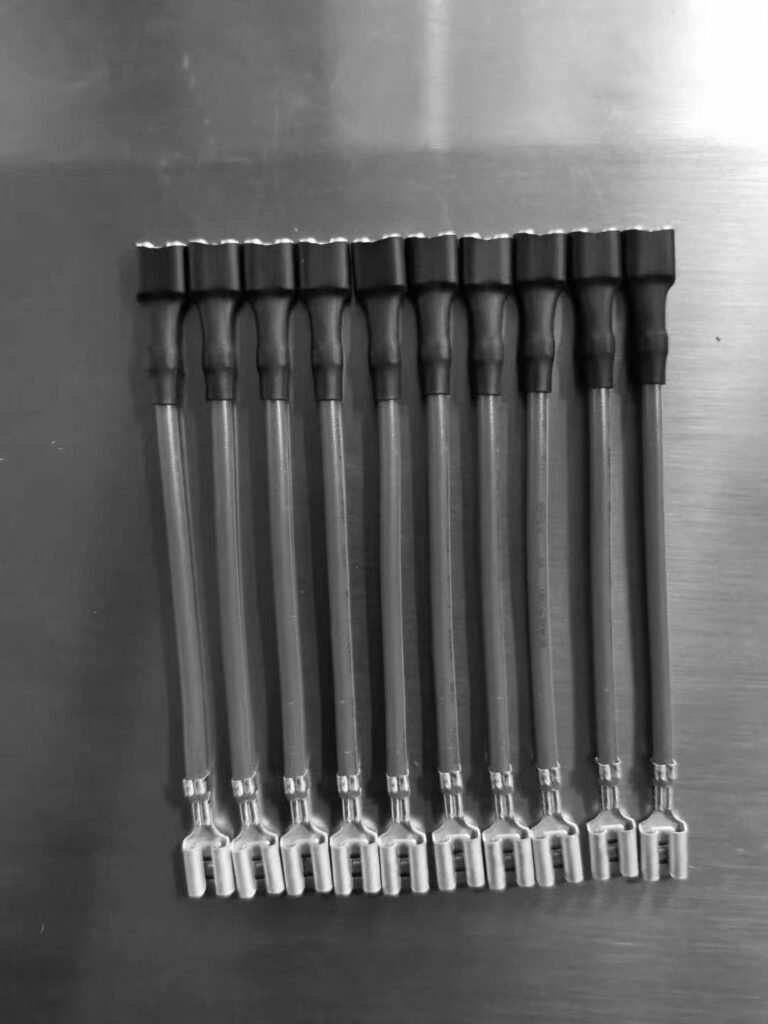

Terminal crimping provides versatility and compatibility across a wide range of wire sizes, terminal types, and applications. Crimping tools and dies are available in various sizes and configurations, allowing for precise and consistent crimping on different wire gauges. Additionally, crimped terminals can accommodate various terminal types, including spade, ring, bullet, and pin terminals, making them suitable for diverse wiring harness applications.

5. Ease of Inspection and Maintenance

Crimped connections are visually inspectable, allowing for easy quality control during production and maintenance inspections. The crimped connection provides a clear indication of a properly executed crimp, ensuring that the connection meets the required standards. This ease of inspection simplifies troubleshooting and maintenance, reducing downtime and improving overall efficiency.

6. Resistance to Environmental Factors

Terminal crimping provides excellent resistance to environmental factors such as moisture, dust, and temperature variations when properly crimped, the connection forms a tight seal, preventing the ingress of contaminants that could compromise the electrical performance. Additionally, crimped connections can withstand a wide range of temperatures, making them suitable for both extreme cold and hot environments.

7. Compliance with Industry Standards

Terminal crimping is widely accepted and recommended by industry standards organizations such as the International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE). Following these standards ensures that crimped connections meet the required specifications for safety, reliability, and performance. Adhering to industry standards also helps maintain consistency and compatibility across different manufacturers and suppliers.

8. Scalability and Efficiency in Production

Terminal crimping offers scalability and efficiency in high-volume production environments. Crimping machines and automated crimping systems can handle large quantities of wires and terminals, ensuring consistent and precise crimping across the production line. This scalability and efficiency contribute to faster production cycles, reduced labor costs, and improved overall productivity.

In conclusion, terminal crimping in wiring harnesses provides numerous advantages, including secure and reliable connections, enhanced electrical performance, cost-effectiveness, versatility, ease of inspection and maintenance, resistance to environmental factors, compliance with industry standards, and scalability in production. These benefits make terminal crimping a preferred choice for various industries, ensuring high-quality electrical connections that meet safety, reliability, and performance requirements.