Cable Assembly: An In-Depth Look at Components, Types and Applications

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

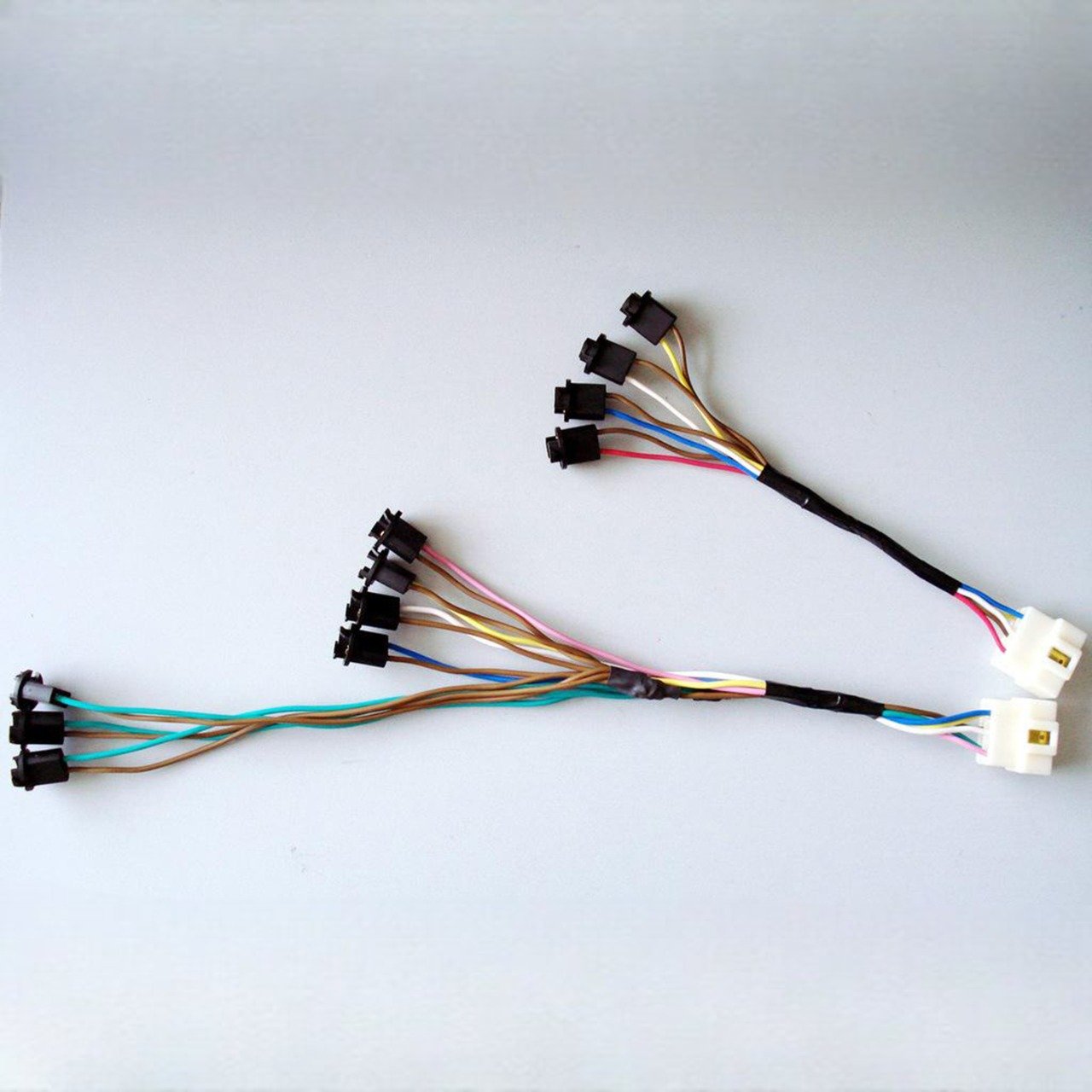

A cable assembly refers to a set of wires or cables bundled together to form a single unit that can be easily installed and connected.

Cable assemblies consist of two main components

a. Cables or wires: These conduct electrical signals or power. They are made of copper or aluminum and insulated with plastic.

b. Connectors: These attach the cables to devices and equipment. Common types include RJ45, USB, HDMI, and barrel connectors.

Cable assemblies are premade, so they simplify installation and reduce the risk of errors.

Variety of types for different applications

a. Power cable assemblies transmit electrical power. They use heavy-gauge wires and connectors to handle high currents.

b. Data cable assemblies transmit data and communication signals. They use twisted-pair wires and connectors like RJ45 for networking.

c. Coaxial cable assemblies transmit high-frequency signals, like those used for cable TV and radio. They have an inner conductor surrounded by insulation and an outer shield.

d. Fiber optic cable assemblies transmit data using light pulses through glass fibers. They use specialized connectors to align the fibers precisely.

e. Hybrid cable assemblies combine different cable types, like power and data, in a single assembly.

Steps of manufacturing process for cable assemblies

a. The required cables and connectors are selected based on the application’s specifications.

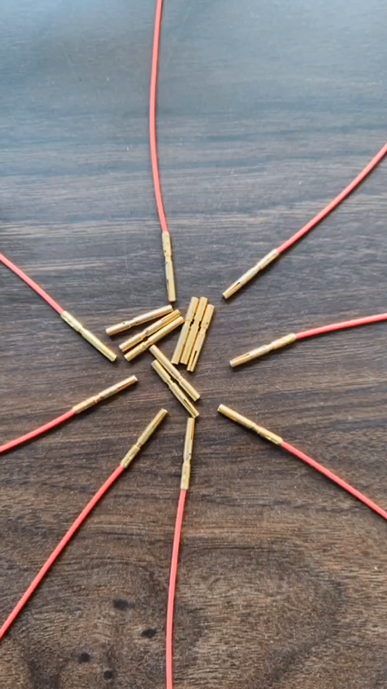

b. The cables are cut to the proper length and stripped to expose the conductor ends.

c. The connector ends are crimped or soldered to the cable ends. This attaches the connector securely and electrically to the cable.

d. The assembly is tested to ensure it meets electrical specifications for continuity, resistance, and signal integrity.

e. The cable assembly is labeled with information like part number, length, and manufacturer.

f. The assembly is packaged for shipping and distribution.

Benefits over individual wires and connectors of cable assemblies

a. Simplified installation – Assemblies are premade, so they are faster and easier to install.

b. Reduced errors – Assemblies are tested before shipping, reducing the chance of installation errors.

c. Standardized lengths – Assemblies come in standard lengths that match application requirements.

d. Improved reliability – Assemblies undergo more rigorous testing than individual components.

e. Lower costs – Assemblies can be cheaper than individually sourced wires and connectors.

Applications and industries of cable assemblies

a. Computers and electronics – To connect internal components and I/O ports.

b. Networking and telecommunications – For LANs, patch panels, and telephone wiring.

c. Automotive – To connect sensors, controls, and infotainment systems.

d. Industrial equipment – To wire machines, robots, and production lines.

e. Medical devices – To connect monitoring equipment, imaging systems and more.

f. Aviation and aerospace – For wiring aircraft, satellites and launch vehicles.

Summary

Cable assemblies provide a convenient, reliable and cost-effective way to connect electrical and electronic devices. By bundling wires and connectors together, cable assemblies simplify installation while maintaining signal integrity and reliability. Their wide range of types and applications make them an indispensable part of modern electronics and machinery.