The background of tape wrapping in wiring harness

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

Tape wrapping in the wiring harness industry has a rich history that dates back to the early days of electrical wiring.

Here’s a brief overview:

1. Early Beginnings

The use of tape for insulating and protecting wires began in the late 19th and early 20th centuries, with the advent of electrical power distribution. Early insulating tapes were made from cloth soaked in a solution that would harden and provide insulation.

2. Introduction of Plastic Tapes

The 1940s saw the introduction of plastic tapes, specifically PVC (Polyvinyl Chloride), which offered superior insulation and durability compared to cloth tapes. PVC tapes quickly became the standard for electrical insulation.

3. Automotive Industry Adoption

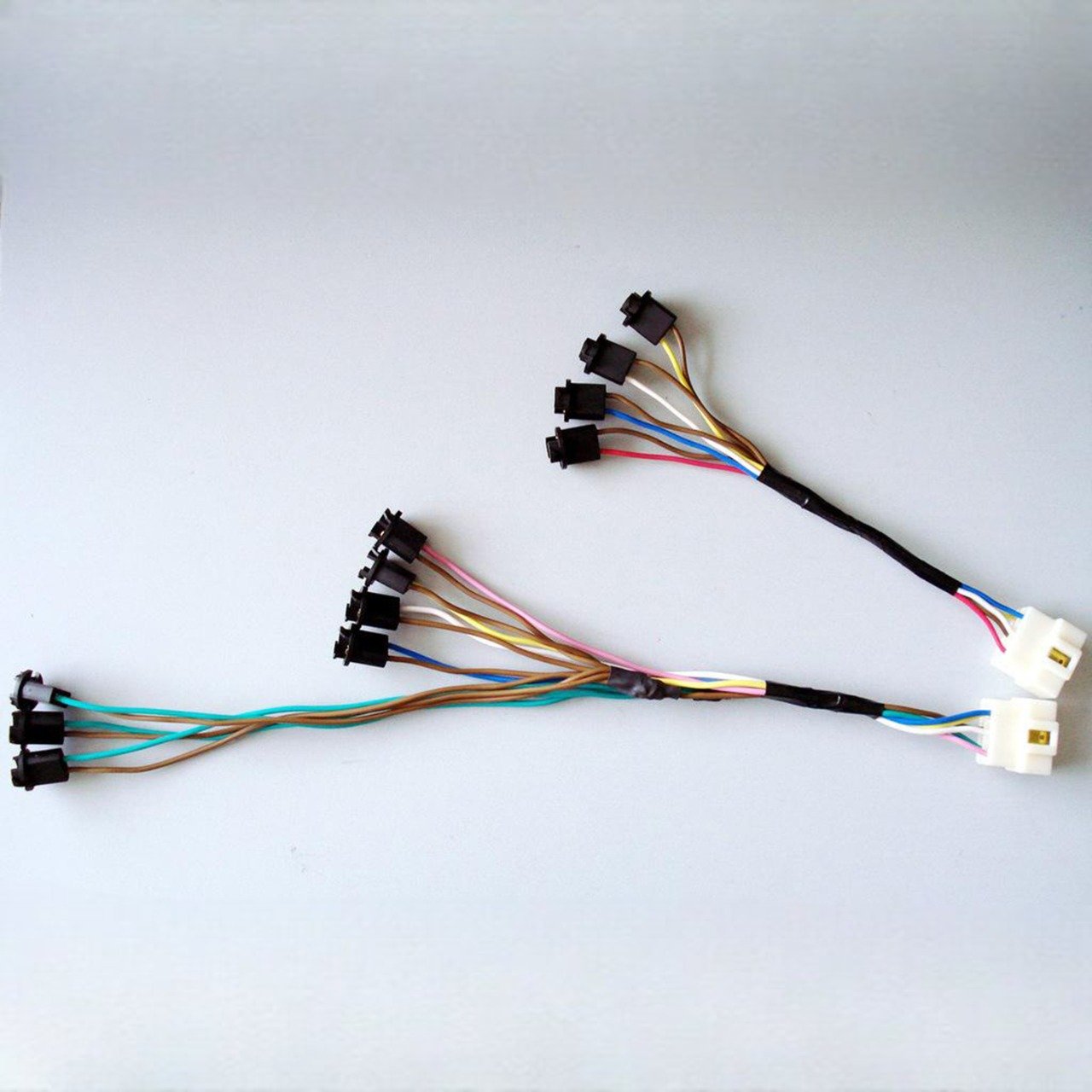

As the automotive industry grew, so did the complexity of the electrical systems within vehicles. The need for a method to organize and protect these wiring systems led to the adoption of tape wrapping in the wiring harness industry.

4. Innovation and Development

Over the years, tape manufacturers have continued to innovate, developing tapes with specific properties to meet the unique needs of the wiring harness industry. For example, tapes with high heat resistance for engine compartments, or tapes with excellent abrasion resistance for areas where wires may rub against metal parts.

5. Customization and Branding

With the growth of the industry, companies started to use tape wrapping as a way to differentiate their products and increase brand visibility. Tapes can be customized with a company’s logo or brand colors, serving as a form of advertising.

6. Environmental Considerations

In recent years, there has been a emphasis on sustainability in the wiring harness industry. This has led to the development of eco-friendly tapes, made from materials that are recyclable or have a lower environmental impact.

Today, tape wrapping is a standard practice in the wiring harness industry, providing protection, organization, and branding opportunities.