Correct use of Heat shrinkable Tubes

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

What is a heat shrinkable tube?

Heat-shrinkable tube, also known as heat-shrinkable casing, heat-shrinkable pipe, etc., heat-shrinkable casing is a kind of insulating casing with the functions of high temperature shrinkage, soft flame retardancy, insulation and corrosion protection. Heat-shrinkable tube is composed of radiation polypolymer, which tightly wraps the cable joint after being heated, so as to achieve the purpose of insulation, sealing and protection.

It is widely used in wiring waterproofing of electronic equipment, sealing and fixing of wire branches, anticorrosion protection of metal pipelines, and prevention of loosening and shedding caused by the relaxation of polymer chains, such as underwater lighting, automobile tubing, advanced wire harness, etc.

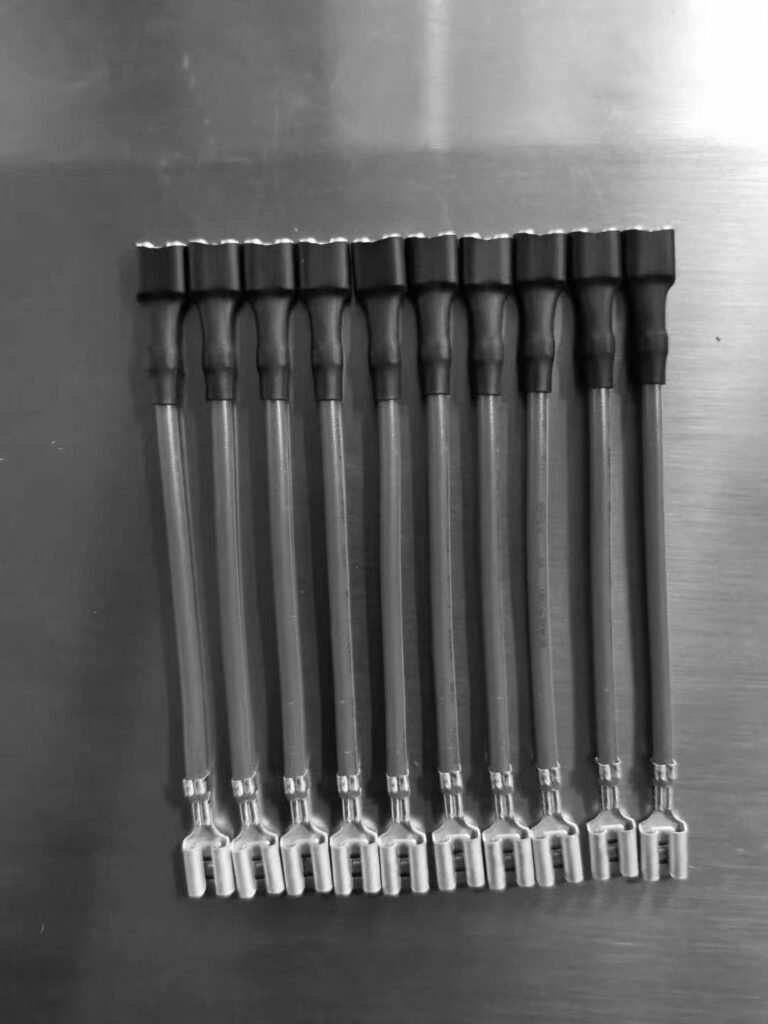

HH-210B https://youtube.com/shorts/YX6556YQ6DY 3 terminal crimped wires

HH-210B https://youtube.com/shorts/-UOUJtxI4Qk copperbelt crimp-mexico customer

HH-210B https://youtube.com/shorts/qPZLTNjXo4I 4-pin flat cable assembly

Initial shrinkage temperature: 70 ℃; Minimum complete shrinkage temperature: 125 ℃; Standard colors are green, yellow, white, transparent, blue, red (other colors can be customized).

According to the difference of voltage, it is divided into low-voltage heat-shrinkable tube, 10KV, 35KV are usually called bus heat-shrinkable casing (high-pressure heat-shrinkable tube, high-pressure bus) and so on.

HH-220B https://youtube.com/shorts/pmEzoBdshqw +laser printer

HH-220B https://youtube.com/shorts/U651OWjz6is +laser printer

Application method of heat shrinkable tube

1. To prepare the material, first understand the diameter of the cable, or calculate the corresponding diameter of the length and width, and select the heat-shrinkable tube whose diameter is slightly larger than the diameter of the cable.

HH-210C https://youtube.com/shorts/Ah3rq1bM0AE large cable assembly new energy

HH-210C https://youtube.com/shorts/ipzxNktMP74 large cable assembly new energy

2. To remove burrs and sharp corners from the cable to prevent cracking caused by piercing the heat-shrinkable tube during retraction, a quick-drying cleaning agent must be used in advance to clean the oil and impurities in the connecting part of the cable and keep it clean.

3. Calculate the length of the package and cut off the corresponding length of the heat shrinkable tube. When cutting the heat tube, the cut should be neat and smooth, and no burr or crack should be produced, so as to avoid the stress concentration caused by heating shrinkage and spread along the crack.

4. Put the heat-shrinkable tube into one end of the cable and move the heat-shrinkable tube to the right position. for the curved cable, the heat-shrinkable tube at the bend should be sorted out to prevent wrinkles.

5. The heating tools generally use a hot air gun, oven or hairdryer. In the heating process, it is necessary to heat from left to right or from right to left, or from the middle to both ends, so as to avoid leaving the air in the heat shrinkable tube. Tightly wrap the cable after shrinkage, do not be too close to the surface of the tube or focus on heating, otherwise it will produce uneven thickness or burn the tube.

Matters needing attention

1. Heat shrinkage tube and heating equipment do not get too close, we must pay attention to the distance between fire and heat shrinkage tube, that is, 4~5cm uniform movement, do not exceed the heat shrinkage tube temperature limit, if the temperature exceeds the temperature limit, will make our products “melting” phenomenon.

2. Choose the appropriate heating tool, when heating and baking, the outer flame is at an angle of 45 degrees with the surface of the heat-shrinkable tube. Be sure to move back and forth to make the heat-shrinkable tube heated as a whole, slowly from one end to the other, heating evenly and avoiding bubbles. Ensure the shape of the heat-shrinkable tube after shrinkage, and trim it after cooling.

HH-680 is processing dual crimp(1 flag terminal) + hst processing

3. The heat-shrinkable tube has different heat-shrinkage ratio, and the specification of the heat-shrinkable tube generally refers to the product of the product of the maximum allowable inner diameter and the shrinkage ratio of the casing after shrinkage.

For example, the shrinkage ratio of the heat-shrinkable tube is 2:1, that is to say, you can choose the heat-shrinkable tube which is twice the diameter of your cable.

For example, if the diameter of the covered object is 20mm, we can choose the heat-shrinkable tube with the maximum diameter of 40mm.

HH-680 is processing terminal crimp &HST processing➕wire soldering

4. For linear objects, such as wires, the heat-shrinkable casing specification of the outer diameter phase size of the product can be selected. The bus row heat-shrinkable casing should be selected for the protection of power stations, electrical cabinets, etc.. Waterproof heat-shrinkable tubes should be selected for sealing requirements.