PCBA: The Backbone of Modern Electronics Manufacturing

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

Introduction

In the world of electronics manufacturing, Printed Circuit Board Assembly (PCBA) plays a pivotal role in bringing electronic devices to life. PCBA involves the assembly of electronic components onto a printed circuit board (PCB), creating a functional and interconnected system. From smartphones and laptops to medical devices and automotive electronics, PCBA is the backbone of modern technology. In this comprehensive article, we will delve into the world of PCBA, exploring its processes, components, advancements, challenges, and its impact on various industries.

Understanding PCBA

Printed Circuit Board Assembly (PCBA) is the process of assembling electronic components onto a printed circuit board (PCB). The PCB serves as the foundation for the electrical connections and mechanical support of the components. PCBA involves various stages, including component placement, soldering, inspection, and testing, to ensure the functionality and reliability of the final product.

Components of PCBA

a. Active Components: Active components are electronic devices that can control the flow of electricity and perform amplification or switching functions. Examples include microprocessors, integrated circuits (ICs), transistors, and diodes.

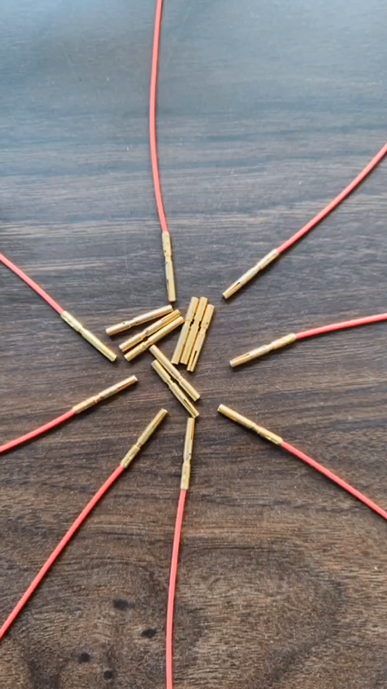

b. Passive Components: Passive components do not require an external power source and do not amplify or switch electrical signals. They include resistors, capacitors, inductors, and connectors.

PCBA Processes

PCBA involves several key processes that ensure the successful assembly of electronic components onto the PCB.

a. Component Placement: In this process, electronic components are accurately positioned and aligned on the PCB according to the design specifications. This can be done manually or using automated pick-and-place machines.

b. Soldering: Soldering is the process of joining the electronic components to the PCB using solder, a metal alloy with a low melting point. Soldering can be done through wave soldering, reflow soldering, or hand soldering techniques.

c. Inspection: After soldering, the PCB undergoes inspection to detect any defects or soldering issues. This can be done through visual inspection, automated optical inspection (AOI), or X-ray inspection.

d. Testing: Once the assembly is complete, the PCB undergoes functional testing to ensure that all components are working correctly and the circuit functions as intended. This can involve various tests, such as electrical testing, functional testing, and environmental testing.

Advancements in PCBA

PCBA has witnessed significant advancements over the years, driven by technological innovations and industry demands.

a. Surface Mount Technology (SMT): Surface Mount Technology revolutionized PCBA by introducing smaller and more compact components that can be mounted directly onto the surface of the PCB. SMT allows for higher component density, improved performance, and reduced manufacturing costs.

b. Miniaturization: The trend towards smaller and more portable electronic devices has pushed PCBA to embrace miniaturization. Advancements in component packaging and assembly techniques have enabled the assembly of tiny components with high precision, allowing for the development of sleek and compact devices.

c. Automation and Robotics: Automation and robotics have transformed the PCBA process, improving efficiency, accuracy, and productivity. Automated pick-and-place machines, soldering robots, and inspection systems have reduced human error, increased throughput, and enhanced quality control.

d. Advanced Inspection Technologies: The introduction of advanced inspection technologies, such as automated optical inspection (AOI) and X-ray inspection, has improved the detection of defects and soldering issues. These technologies provide high-resolution imaging, allowing for thorough inspection of complex PCB assemblies.

e. Lead-Free Soldering: Environmental concerns and regulations have led to the adoption of lead-free soldering in PCBA. Lead-free solder alloys, such as tin-silver-copper (SnAgCu), offer improved reliability, reduced environmental impact, and compliance with RoHS (Restriction of Hazardous Substances) directives.

Challenges in PCBA

PCBA is not without its challenges, and manufacturers must address these to ensure successful assembly and reliable products.

a. Component Sourcing and Availability: The availability of electronic components can pose challenges, especially for specialized or high-demand components. Manufacturers must establish reliable supply chains and manage component sourcing to avoid delays or production issues.

b. Design for Manufacturability (DFM): Designing PCBs for efficient and cost-effective manufacturing is crucial. PCB designs must consider factors such as component placement, solderability, thermal management, and manufacturability to optimize the PCBA process.

c. Quality Control and Testing: Ensuring the quality and reliability of PCBA requires robust quality control measures and comprehensive testing. Manufacturers must implement stringent inspection and testing protocols to detect defects, ensure proper soldering, and validate the functionality of the assembled PCBs.

d. Rapid Technological Advancements: The rapid pace of technological advancements poses challenges for PCBA. Manufacturers must stay updated with the latest technologies, components, and assembly techniques to meet evolving industry demands and maintain a competitive edge.

e. Cost Management: PCBA can involve significant costs, including component costs, equipment investments, and labor expenses. Manufacturers must carefully manage costs while maintaining quality and meeting customer expectations.

Impact of PCBA on Industries

PCBA has a profound impact on various industries, enabling the development of innovative electronic devices and systems.

a. Consumer Electronics: PCBA is at the core of consumer electronics, including smartphones, tablets, laptops, and home appliances. It enables the functionality, performance, and connectivity of these devices, enhancing the consumer experience.

b. Automotive: PCBA plays a critical role in automotive electronics, powering advanced features such as infotainment systems, driver-assistance systems, and electric vehicle components. It ensures reliable and efficient operation in the demanding automotive environment.

c. Healthcare: PCBA is vital in medical devices and equipment, enabling accurate diagnostics, patient monitoring, and life-saving treatments. It contributes to advancements in healthcare technology, improving patient care and outcomes.

d. Industrial Automation: PCBA is essential in industrial automation systems, including robotics, control systems, and sensors. It enables precise control, data acquisition, and communication, enhancing productivity and efficiency in industrial processes.

e. Aerospace and Defense: PCBA is critical in aerospace and defense applications, where reliability, durability, and performance are paramount. It enables communication systems, avionics, navigation systems, and defense electronics.

Future Trends in PCBA

The future of PCBA is shaped by emerging trends and technologies that will further enhance its capabilities.

a. Internet of Things (IoT) Integration: PCBA will continue to integrate IoT connectivity, enabling seamless communication between devices and facilitating the growth of smart homes, cities, and industries.

b. Artificial Intelligence (AI) and Machine Learning: AI and machine learning algorithms will be integrated into PCBA processes, enabling intelligent decision-making, predictive maintenance, and optimization of manufacturing processes.

c. 5G Connectivity: The advent of 5G technology will drive the demand for PCBA capable of handling high-speed data transfer, low latency, and increased connectivity, supporting the growth of IoT, autonomous vehicles, and smart infrastructure.

d. Advanced Materials and Packaging: The development of advanced materials, such as flexible substrates and 3D-printed electronics, will enable new form factors and applications. Advanced packaging techniques, such as system-in-package (SiP) and chip-on-board (COB), will enhance integration and performance.

e. Sustainability and Green Manufacturing: PCBA will continue to embrace sustainable practices, including the use of eco-friendly materials, energy-efficient processes, and responsible waste management, contributing to a greener and more sustainable electronics industry.

Conclusion

Printed Circuit Board Assembly (PCBA) is the backbone of modern electronics manufacturing, enabling the assembly of electronic components onto PCBs and bringing electronic devices to life. PCBA processes, advancements, and challenges shape the development of innovative electronic products across various industries. As technology continues to evolve, PCBA will play a crucial role in driving the growth of smart homes, connected devices, and sustainable electronics manufacturing, shaping the future of our digital world.