Crimping Method for Pin Terminals and Shielding-rings

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

The automobile terminal is one of the main connecting components in the wiring harness, which is connected by the wire and the terminal after crimping, which plays the role of transmitting current and signal and satisfies the normal use of the vehicle.

According to the different requirements of the terminal, it is mainly divided into two styles: open terminal and closed terminal.

Open terminals are mainly chain–belt structure, which can achieve continuous crimping on the equipment, and relatively a small number of large square terminals (more than 8 mm²) are single terminals, which need a single crimping.

Closed terminals are also called pin terminals, all of which are single terminals. When crimping, the wire needs to be pierced into the crimping hole of the terminal before crimping.

With the development of new energy vehicles, high-voltage wire harness begins to increase gradually, and the main form of terminal is closed terminal.

Open terminals are commonly used in wire harness, and the crimping method is relatively simple, so there is no more analysis here.

Today, we mainly analyze the crimping mode of closed terminal and shielding ring in high voltage wire harness.

Shielding ring crimping is a unique crimping type in high-voltage wire harness, which mainly plays the role of shielding connection, so the function will not be described in detail here.

The main crimping methods of pin terminals are: hexagon crimping, hexagon 2 spots crimping, MW crimping, 4 spots crimping.

The main crimping methods of shielding ring are: hexagon crimping, hexagon 2 spots crimping, 6 spots crimping.

Let’s analyze them from their crimping mode.

1. Closed terminal crimping

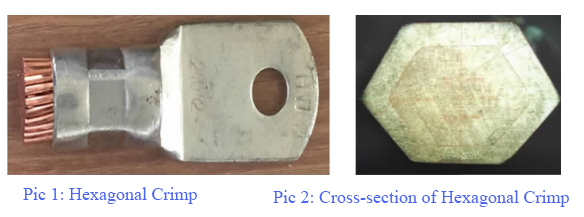

1).Hexagon crimping

The crimping on 6 sides of the terminal is generally suitable for more than 8 mm² conductors, and the crimping is carried out when the wire and the terminal square match completely. After crimping, the tests of cross-section and pull-out force can be qualified.

Crimping equipment mainly uses hydraulic equipment to ensure soft crimping in the process of terminal crimping and to avoid terminal cracks.

HH-350S https://youtube.com/shorts/qMEKqHWaSRA pin

HH-350S https://youtube.com/shorts/XIjfp2u3KtU hexagon crimp

In the sample stage, most of the hexagon hydraulic special equipment without changing die is used, and the special hydraulic equipment is used according to the crimping mode in batch.

The hexagon crimping diagram of the terminal is shown in Pic 1 and Pic 2.

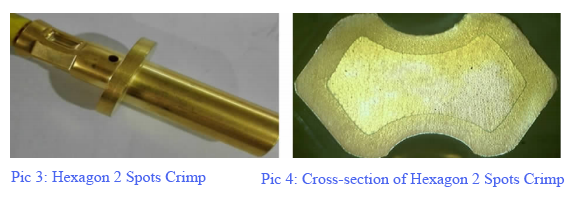

2). Hexagon 2-Spot Crimping

Hexagon 2-point crimping is generally suitable for wires above 8 mm², and crimping is carried out when the combination of wire and terminal is slightly less than the terminal diameter, and the cross-section and pull-out force after crimping are also qualified.

Crimping equipment mainly uses hydraulic equipment.

The hexagon 2-spot crimping is shown in Pic 3, and its cross-section is shown in Pic 4.

3). MW Crimping

MW crimping, generally suitable for more than 8 mm², wire and terminal match slightly less than the terminal diameter of the case.

However, in order to ensure the deformation of the terminal crimping part and the good contact coordination, MW crimping can be preferred, and the cross-section and pull-out force after crimping are also qualified.

With the increasing number of new energy vehicles, crimping stability is also gradually increasing. MW crimping is a superior crimping method based on hexagon 2-spot crimping, which is worth popularizing from terminal deformation to cross-section effect analysis.

See Pic 5 for MW crimping and Pic 6 for the cross-section of MW crimping.

4). 4-spot Crimping

4-point crimping is generally suitable for wires below 6 mm². Crimping is carried out when the wire and terminal match well, and the tests for cross-section and pull-out force after crimping are also qualified.

In the crimping process, it is necessary to insert the wire into the crimping hole of the terminal, and then crimp the wire and the terminal. In the crimping process, it is necessary to prevent the terminal from falling off and affect the operation efficiency.

4-spot crimping and its cross-section are shown in Pic 7 and Pic 8.

2.Shielding-ring Crimping

1).Hexagon crimping

The hexagon crimping on the shielding ring is generally suitable for more than 3 mm² conductors. It is a crimping mode with good coordination between the wire shielding net and the shielding ring, and the pull-out force is qualified after crimping.

In general, when the gap between the shielding ring and the shielding net and wire is small and close, this crimping method is adopted, which is widely used, and it is one of the commonly used crimping methods of shielding ring.

The hexagon crimping of the shielding ring are shown in Pic 9.

2). Hexagon 2-spot crimping

Hexagon 2-spot crimping is generally suitable for crimping mode of wire shielding net and shielding ring above 8 mm², and the pull-out force is qualified after crimping.

Usually, when the gap between the shielding ring and the shielding net and the wire is slightly larger, this crimping method is adopted, and the number of crimping spots is determined according to the length and size of the shielding ring, which is also one of the commonly used crimping methods of the shielding ring.

The hexagon 2-spot crimping of the shielding ring is shown in Pic 10.

3). 6-spot Crimping

The 6-spot crimping of the shielding ring is generally suitable for the crimping mode of the shield net of 10mm² wires and the shielding ring, and the pull-off force is qualified after crimping.

In general, this crimping method is adopted when the gap between the shielding ring and the shielding net and the wire is large.

The main reason for using this method is that the connector shielding ring and the wire do not match, and the toughness of the material of the shielding ring is high, otherwise cracks will appear after the crimping of the shielding ring and the conductor, and it will lead to unqualified product quality.

The 6-spot crimping of the shielding ring is shown in Pic 11.

3.Summary

In the actual production process of high voltage wire harness, crimping is rated as a key process.

In the process of developing the crimping die, the crimping engineer should carefully analyze the matching of the connector structure and the wire. It is necessary to analyze the connector assembly instructions, find out the connector structure status, and put forward the development list and requirements to the die developer in order to ensure that there are no problems in the use process.

Through the above analysis, each crimping method has its own characteristics, as long as careful analysis, we can develop a suitable crimping die, so as to meet the crimping requirements and ensure product quality.