R&D of NVH for Motor driven by New Energy (Part 1)

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

Status quo of drive motor

The driving motor is the core power source of new energy vehicles and hybrid vehicles. Based on the electromagnetic induction effect, the driving motor converts the electric energy provided by the whole vehicle into mechanical energy and drives the whole vehicle.

According to the input current, the driving motor can be divided into two forms: DC motor and AC motor.

At present, the mainstream drive motor is AC motor, which transmits AC power to the stator (usually silicon steel sheet with copper coil, fixed) to produce a rotating magnetic field, and the rotor (made of electromagnet, permanent magnet or silicon steel sheet) is affected by the rotating magnetic field to form a rotating torque.

According to the speed consistency of the rotor and the stator, the AC motor can be divided into synchronous motor and asynchronous motor.

At present, the main driving motors in the new energy market are permanent magnet synchronous motor and squirrel cage induction motor, in which permanent magnet synchronous motor accounts for the absolute mainstream share of motor in the domestic automobile construction force.

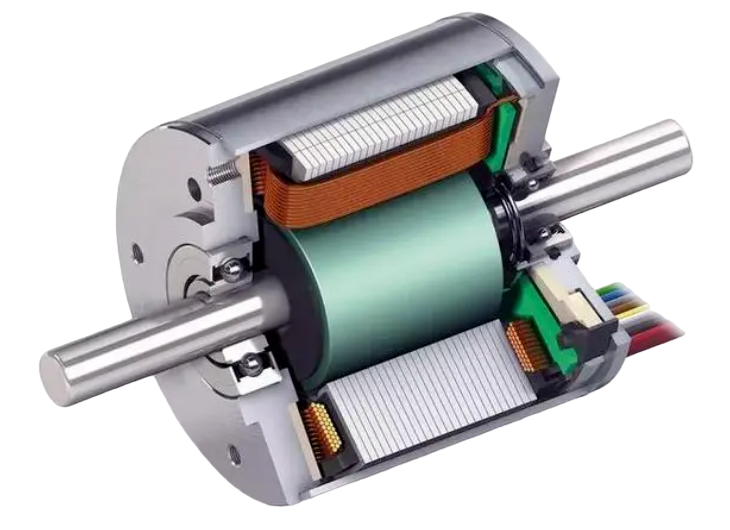

The main parts of the driving motor generally include: rotor, stator, wire harness, shell, end cover, etc., in which the stator, winding, bearing and rotor are in the order of value content, and the cost accounts for 19%, 17%, 12% and 11% respectively.

If the drive motor is always divided downstream, the stator core, rotor core, stator winding, bearing, end cover and other parts are in the middle, and the raw materials such as copper wire, aluminum alloy, silicon steel sheet and permanent magnet are upstream.

New energy vehicle drive motor is a kind of industrial motor. In view of the special environment of vehicle working conditions, the special performance differences between new energy vehicle drive motor and traditional industrial motor are mainly reflected in large starting torque, high power density, wide speed regulation range, strong heat dissipation demand, wide efficiency range and excellent NVH performance.

1). Large starting torque

New energy vehicles put more emphasis on performance indicators such as start response and 100 km acceleration. The driving motor of new energy vehicles requires higher torque when starting or at low speed, raising the speed of the vehicle to the expected value in the shortest time.

2). High power density

The vehicle drive motor has strict requirements of weight, volume and power.

The weight and size of the motor directly affect the dynamic performance and layout space of the automobile. The direction and difficulty of motor design is to improve the power weight density and power volume density as much as possible.

3). Wide speed regulation range

The wide speed regulation range of the drive motor can make the new energy vehicle save the traditional multi-gear gearbox and only use the fixed gear set to achieve a wide speed regulation range and effectively reduce the cost.

4). Strong demand for heat dissipation

Due to the high power density of the drive motor of new energy vehicles, the problem of heat dissipation follows.

The traditional powertrain of a 150KW is about 409L, while the powertrain of an electric vehicle with the same peak power can reach 82L, only 20% of that of the conventional powertrain.

The design of small volume and high power can bring some problems, such as heat dissipation, mechanical vibration, electromagnetic compatibility, NVH howling and so on.

The energy conversion efficiency of the motor is more than 90%, the peak efficiency is about 95%, the average energy loss is about 10%, and this 10% of the energy loss is mostly reflected in the form of heating, so the heat dissipation demand of the drive motor is strong.

5). Wide range of efficiency

New energy vehicles, especially pure electric vehicles, are powered by on-board battery packs, and the efficiency of the motor directly affects the mileage, so the efficiency of the motor is very high. The driving motor of the new energy vehicle needs to have as wide an efficient operation range as possible. Under normal urban road conditions, the vehicle will not start frequently, nor will it continue to run at ultra-high speed. More often, the acceleration overtaking or deceleration braking action is carried out in the uniform speed driving, so the operation efficiency of the middle part is particularly important.

6). NVH performance is excellent

Compared with traditional industrial motors, due to the picky nature of customers, new energy vehicle drive motors need to have better NVH performance.

Manufacturers and mainframe factories spend a huge amount of manpower and financial resources on optimizing motor noise. At present, the NVH development of driving motor has been mature.