Top 10 reasons of tape wrapping in the wiring harness

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

1. Protection

Tape wrapping provides a protective layer to the wires, shielding them from environmental factors such as heat, cold, moisture, and dust. This helps to prolong the lifespan of the wiring harness and prevent potential malfunctions.

2. Insulation

Tapes, especially those made from materials like PVC or cloth, offer excellent insulation properties. This is crucial in preventing electrical leaks and ensuring the safety of the wiring system.

3. Abrasion Resistance

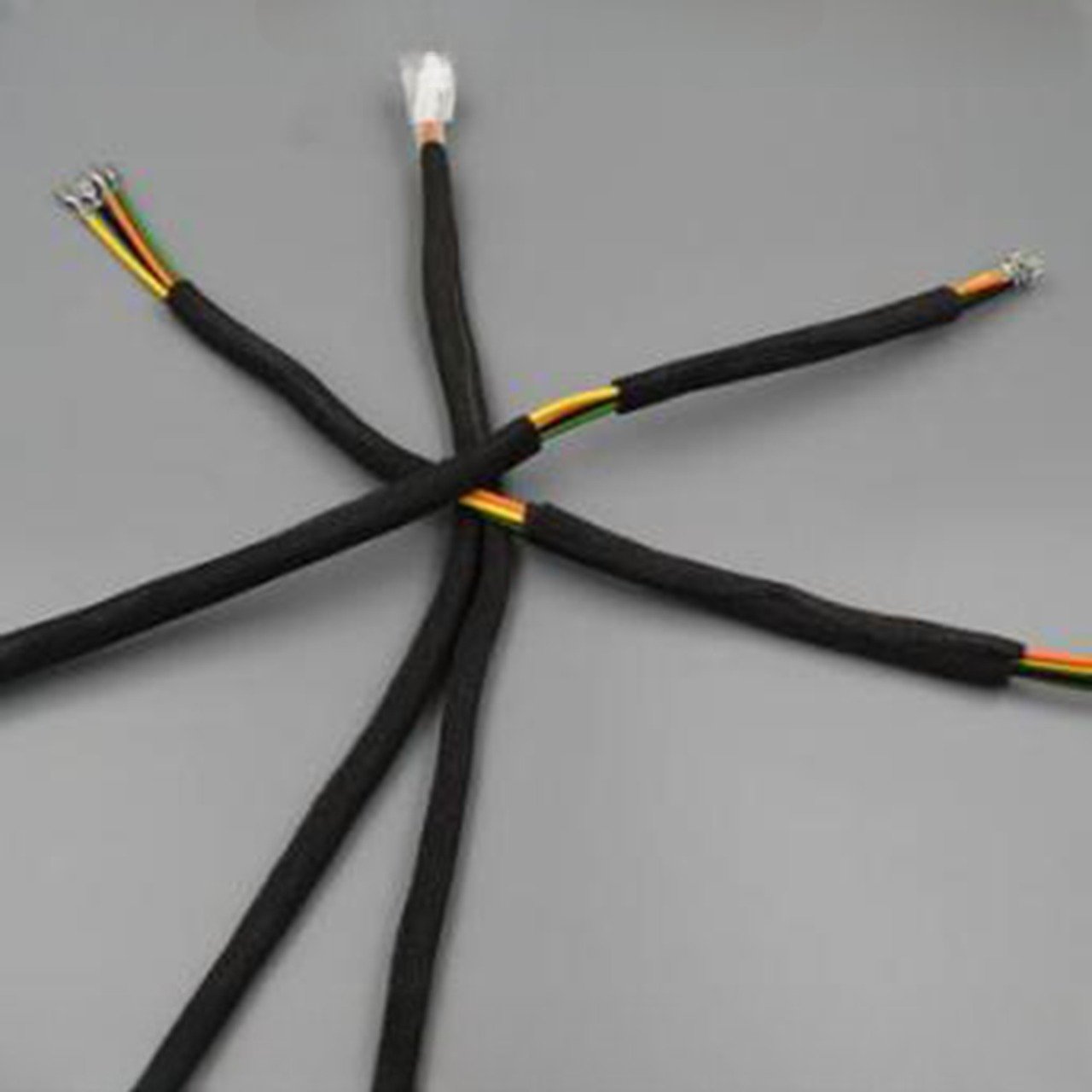

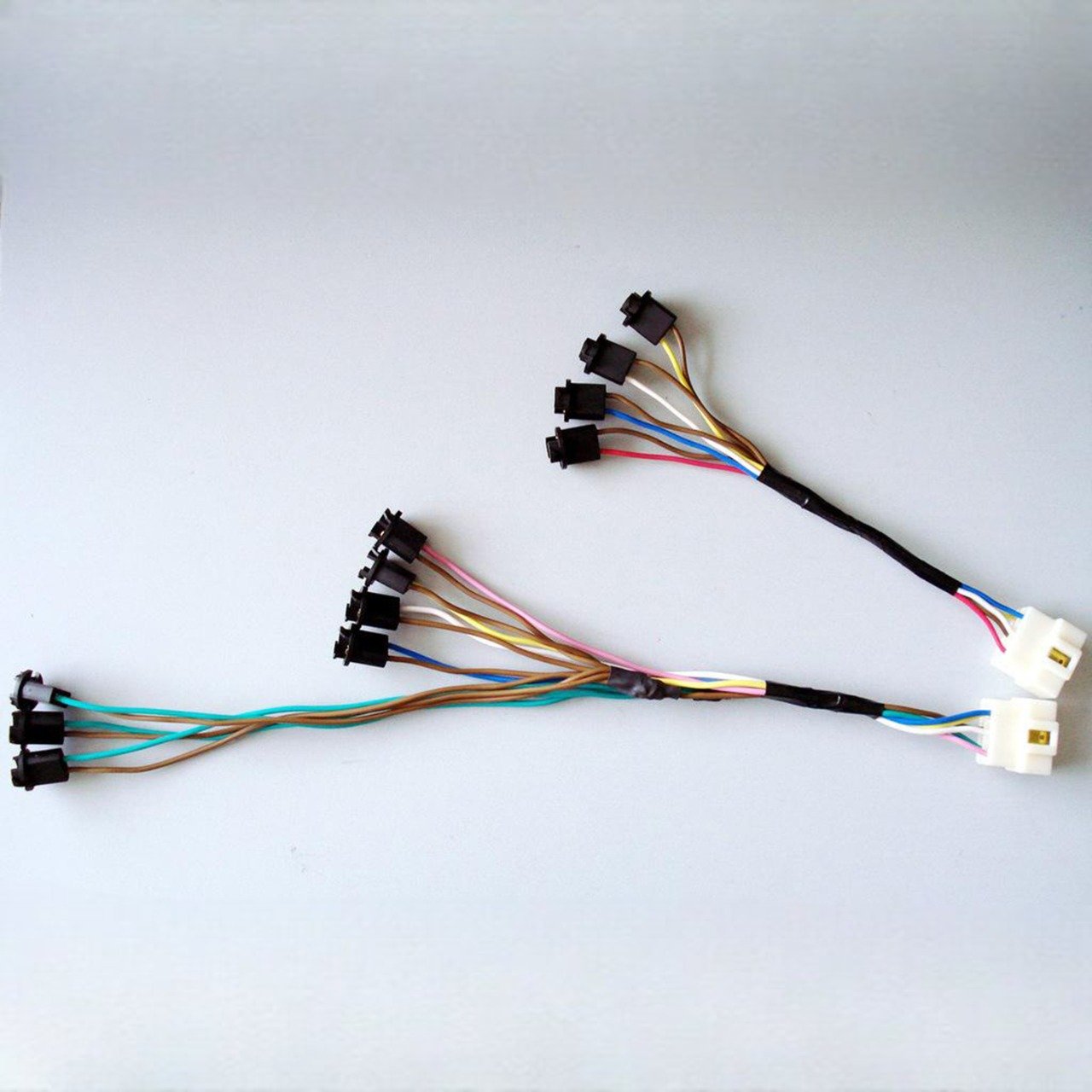

Wires in a harness can rub against each other or against the body of the vehicle or machine. Tape wrapping provides a buffer, reducing the risk of wear and tear caused by constant friction.

4. Noise Reduction

When wires vibrate or move, they can create noise. Tape wrapping helps to dampen this noise, contributing to a quieter operation of the vehicle or machinery.

5. Organisation

Tape wrapping helps to keep wires bundled neatly together. This makes the harness easier to install and manage, and it also simplifies the process of identifying and troubleshooting any issues.

6. Flexibility

Tapes are flexible, allowing them to conform to the shape of the wiring harness. This makes them an ideal solution for wrapping complex harness configurations.

7. Cost-Effective

Compared to other methods of protection, such as conduit or braided sleeving, tape wrapping is often more cost-effective. It requires less material and labor, which can lead to significant cost savings.

8. Variety of Materials

Tapes come in a variety of materials, each with its own set of properties. This allows manufacturers to choose the most suitable tape for their specific application.

9. Ease of Installation

Tape wrapping is a straightforward process that doesn’t require any special tools or skills. This makes it a practical choice for both manufacturers and end-users.

10. Brand Visibility

Tapes can be customised with a company’s logo or brand colors. This not only enhances the aesthetic appeal of the wiring harness but also serves as a form of advertising.

In conclusion, tape wrapping plays a crucial role in the harness industry. It offers a multitude of benefits, from protection and insulation to cost savings and brand visibility. An operator or plant manager, or anyone in wiring harness, it’s essential to understand these advantages to effectively promote the use of tape wrapping in this industry.