Application of Terminal in Automobile Wire Harness(B)

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

Crimping type of terminal

This paper describes the crimping shape at the tail of the terminal and at the wire insulation.

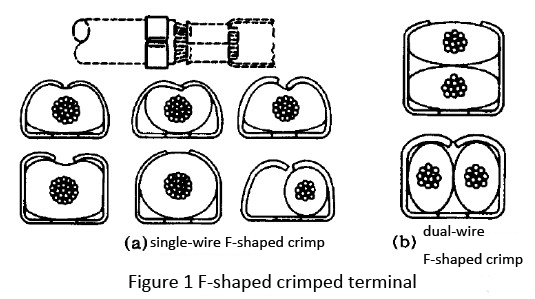

F-shaped crimping

In the F-shaped crimping, after the cold crimping connection, the terminal is not allowed to pierce into the wire core in the terminal insulation crimping area, the single-wire F-shaped crimping is shown in figure 1a, and the double-wire F-shaped crimping is shown in figure 1b.

There are many applications of this crimping type,which is used in a large part of the inner terminals of receptacles used in domestic car wiring harness, such as Guangzhou Toyota, FAW and so on.

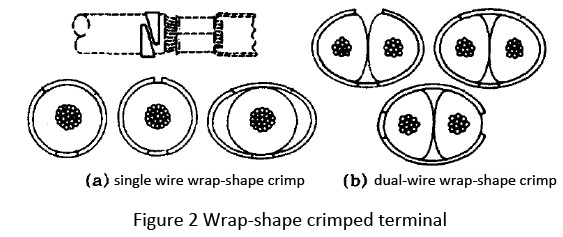

Wrap crimping

After the cold crimping of the terminal, it is not allowed for the terminal to pierce into the insulating layer of the wire. After crimping, the two outer sides of the insulation crimping area must be in a pair of parallel planes, single-wire WRAP crimping as shown in figure 2a, and double-wire WRAP crimping as shown in figure 2b. This crimping type is used in the inner terminal of the instrument display and combination switch docking receptacles in the instrument panel wire harness of China Junjie, and also used in the small terminals in the engine wiring harness and ECU docking receptacles of Great Wall Spirit, Harvard M1, Xuan Li and BYD F3, F3DM hybrid power.

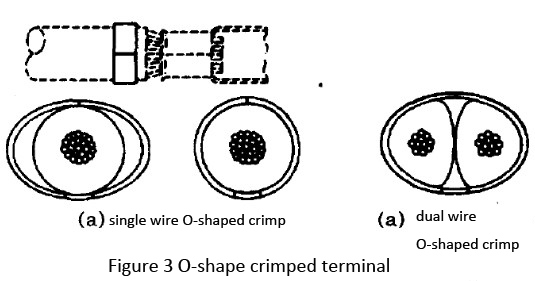

O-shaped crimping

After the cold crimping, the terminal piercing into the insulating layer of the wire is not allowed in the insulation crimping zone. After crimping, the terminal sealing port of the insulation crimping area is in direct contact or separated. The single-wire O-shaped crimping is shown in figure 3a. Double-wire O-shaped crimping is shown in figure 3b. This crimping type is used in the terminal base docked with ECM in the instrument panel wire harness of China Junjie.

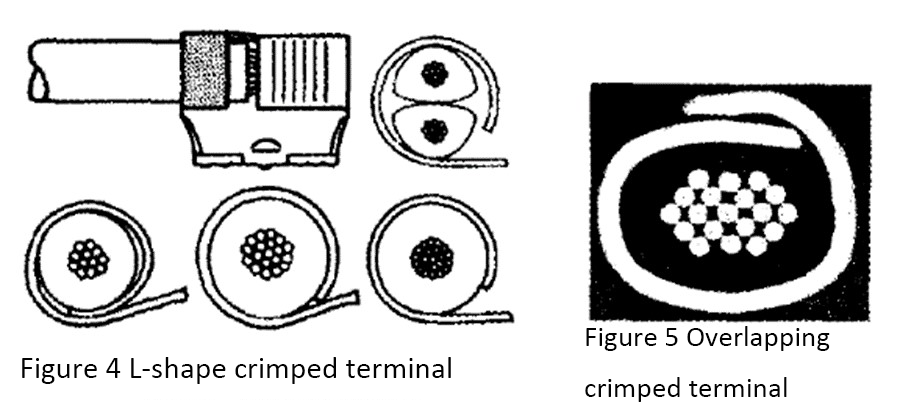

L-shaped crimping

This crimping method is used in the crimping of flag-shaped terminals and is rarely used. Figure 4 shows L-shaped single and double wire crimping.

This crimping type is used in the terminal base which is docked with the hand brake switch in the China Junjie.

Overlapping crimping

After the cold crimping, the terminal is not allowed to pierce into the wire insulation layer in the insulation crimping area. The terminal sealing ports are stacked together after the terminal crimping. When using this type of crimping, the contact surface between the terminal and the wire insulation is the largest, as shown in figure 5.

This crimping type is applied to the terminals in the receptacle which are docked with the gas generator and the hour spring in the airbag wire harness of China Junjie and Changan Yuexiang of domestic cars.

Non-standard special tail crimping

Usually when receptacles with a secondary tail self-locking, the terminal must do special crimping treatment in application.The commonly used ones are high tail and wide tail crimping, that is, the crimping height or width of the insulation crimping zone must be within a numerical section to meet the self-locking requirements, otherwise the tail secondary self-locking may fail, resulting in lower quality and more hidden dangers.

The tail crimping shape of the terminal is determined by the receptacle itself. in general, there are three types of non-standard special tail crimping.

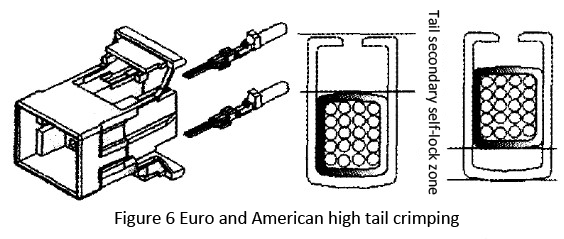

European and American high tail crimping

When the terminal and the receptacle are assembled correctly, this crimping type must be used when the direction of the crimping joint of the terminal core and the insulation is on the same side of the receptacle, as shown in figure 6, otherwise the self-locking characteristic can not be satisfied.

The advantage of this crimping type is that the terminal has good stability in the receptacle and will not appear the phenomena of dislocation and rotation;while the disadvantage is that the contact surface between the terminal and the wire in the insulated crimping zone is small, and the fixing performance of the wire in the insulated crimping zone is not good.

This crimping type is applied in the terminals in the docking receptacle between China Junjie instrument wiring harness and engine cabin wire harness, as well as with anti-theft device, electric rearview mirror switch, seat belt switch, license plate lamp and rear combination lamp.

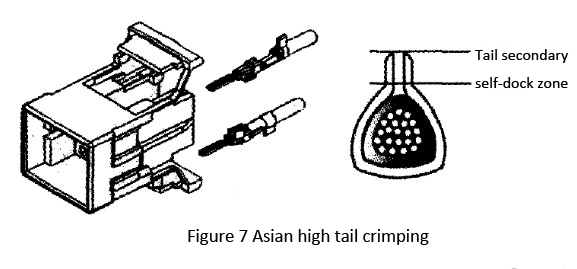

Asian high tail crimping

When the terminal and the receptacle are assembled correctly, this crimping type must be used when the direction of the crimping joint of the terminal core and the insulation is on both sides of the receptacle, as shown in figure 7,

because this crimping type can better ensure the maximum contact area between the terminal and the wire.

The deficiency is that when the matching accuracy of the terminal and the receptacle is not high, the terminal has a certain range of rotation after assembly, which affects the assemblability of the terminal and docking terminal.

This crimping type is used in the terminals in the receptacle docked with scraping, washing and horn switches in China Junjie instrument wire harness, and also used in the terminals in the receptacle docking with the glass elevator switch on the dazzling left front door wire harness of the Great Wall, as well as in the engine room wiring harness, instrument panel wire harness and the terminals in the receptacle docking with the floor wire harness of the Great Wall Spirit.

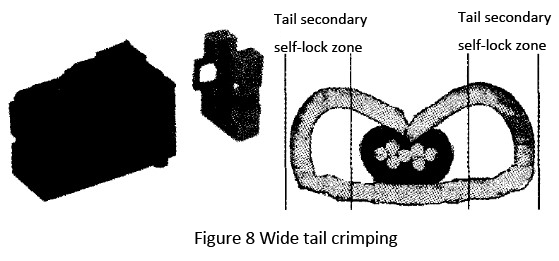

Wide tail crimping

This crimping method is suitable for terminals with specifications above 6.3 and is rarely used, and can sometimes be used in the receptacle of some power plug-ins, as shown in figure 8.

This crimping type is used in the terminals in the power socket receptacle of the Great Wall Spirit’s engine room wiring harness and the central distribution box, as well as in the relay terminal in the No. 2 distribution box in the engine room wiring harness.

Summary

In this paper, through the description of each functional part and functional area of the terminal, and some important parameters of terminal cold crimping (crimping height and width, crimping head length, cutting length of material belt, requirements of front and rear bell mouth, position of wire core and insulation layer in buffer transition zone, terminal deformation), as well as six crimping types are analyzed in detail for reference and correction.