The Impact of Miniaturization of Connectors on the Automotive Industry

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

Introduction

In today’s rapidly evolving automotive industry, technological advancements continue to shape the way vehicles are designed and manufactured. One such innovation that has gained significant attention is the miniaturization of connectors. These tiny yet powerful components play a crucial role in the functioning of various systems within a car. In this article, we will explore the implications of connector miniaturization on the automotive industry, highlighting its benefits, challenges, and potential future developments.

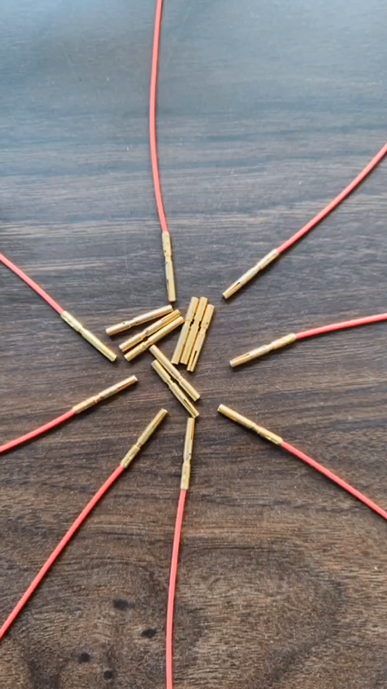

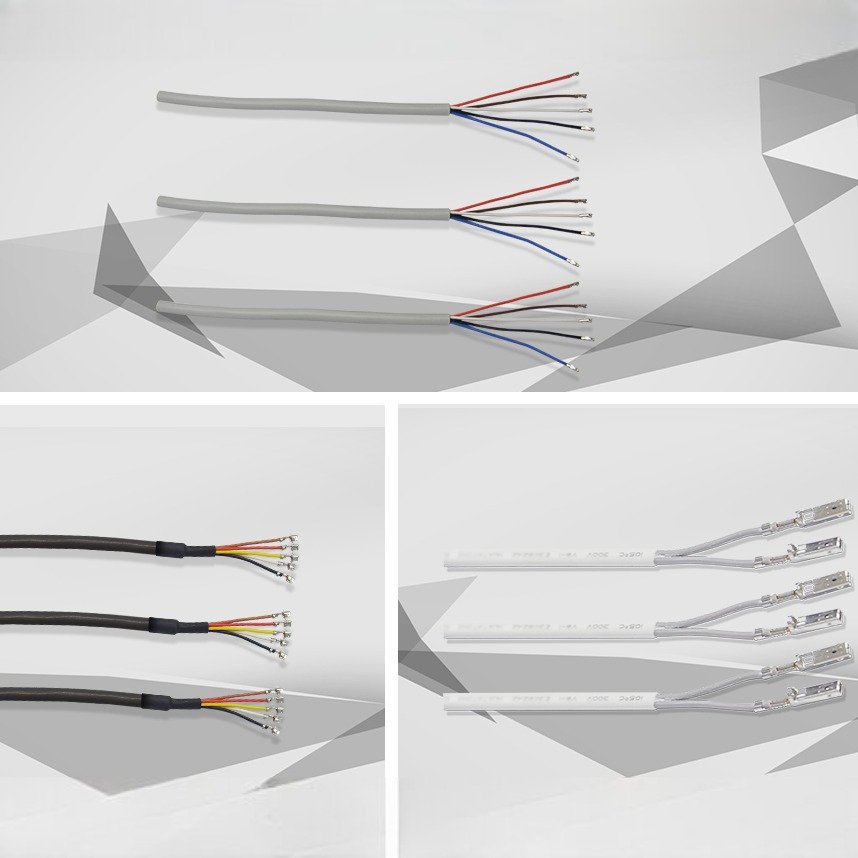

Understanding Connector Miniaturization

Connector miniaturization refers to the process of reducing the size of connectors while maintaining or even enhancing their performance capabilities. This trend has been driven by the need for more compact and lightweight vehicles, improved fuel efficiency, and the integration of advanced technologies.

Enhanced Space Efficiency

One of the primary advantages of miniaturized connectors in cars is the significant space savings they offer. By reducing the size of connectors, manufacturers can optimize the layout of electrical systems, allowing for more efficient use of available space. This, in turn, enables the integration of additional features and functionalities within the vehicle without compromising on design or performance.

Weight Reduction and Fuel Efficiency

Miniaturized connectors contribute to weight reduction in vehicles, which is a critical factor in achieving better fuel efficiency. By replacing larger connectors with smaller ones, automakers can reduce the overall weight of the electrical system, leading to improved fuel economy and reduced emissions. This is particularly important as the industry moves towards electric and hybrid vehicles, where every ounce of weight reduction matters.

Enhanced Reliability and Performance

Despite their smaller size, miniaturized connectors are designed to deliver high levels of reliability and performance. Advanced materials and manufacturing techniques ensure that these connectors can withstand harsh environmental conditions, vibrations, and electrical stresses. This reliability is crucial for the seamless operation of various vehicle systems, including powertrain, infotainment, safety, and advanced driver-assistance systems (ADAS).

Integration of Advanced Technologies

Connector miniaturization opens up new possibilities for the integration of advanced technologies in vehicles. With smaller connectors, automakers can incorporate features such as advanced sensor systems, wireless connectivity, and autonomous driving capabilities. These technologies enhance the overall driving experience, improve safety, and pave the way for the future of mobility.

Challenges and Considerations

While connector miniaturization offers numerous benefits, it also presents challenges that need to be addressed. One such challenge is the increased complexity of electrical systems due to the higher number of connectors required. This complexity demands meticulous planning, precise installation, and thorough testing to ensure optimal performance and reliability.

Future Developments

As technology continues to advance, connector miniaturization is expected to evolve further. The automotive industry is witnessing the emergence of next-generation connectors, such as micro connectors and nano connectors, which are even smaller and more efficient. These advancements will enable the integration of more sophisticated features, such as augmented reality displays, advanced sensor networks, and seamless vehicle-to-vehicle communication.

Conclusion

The miniaturization of connectors is revolutionizing the automotive industry, offering a multitude of benefits ranging from space efficiency and weight reduction to enhanced reliability and the integration of advanced technologies. As automakers strive to meet the demands of a rapidly changing market, connector miniaturization will continue to play a pivotal role in shaping the vehicles of the future. By embracing this trend, manufacturers can create more innovative, efficient, and connected cars that cater to the evolving needs of consumers while driving the industry towards a sustainable and technologically advanced future.