Inspection Specification of Wire Cutting

-

@

Mark Ji

@

Mark Ji

- Last updated

Table of Contents

1). Wire Cut off/Damaged

Definition:

The inner conductor of the wire is removed, resulting in a reduction in the original size of the conductor.

Possible Reasons:

1. The cutting bezel is poorly installed.

2. The central position of the conductor in the wire exceeds the standard.

Control Standard:

1.Wire cut/damaged of solid conductor is not acceptable

2.For stranded conductor, each strand wire is cut off by less than 50% of the diameter is acceptable, while exceeding it is not acceptable.

Basic Principles:

1.Conductor shaving off results in a decrease in the diameter of the conductor, which may cause the terminal to break.

2.The decrease of the conductor diameter will lead to the increase of the resistance value, which will affect the electrical performance.

2).Conductor Disposed by Poor Splitting

Definition:

In the process of dealing with the cutting and separation of flat cables, improper cutting leads to insulation damage and conductor exposure.

Possible Reasons:

- The cutting bezel is poorly installed.

2. Cable material defect: the cable interval exceeds the standard.

Control Standard:

Conductor exposure by poor splitting is not acceptable.

Basic Principles:

Exposed conductors can easily lead to electrical short circuits.

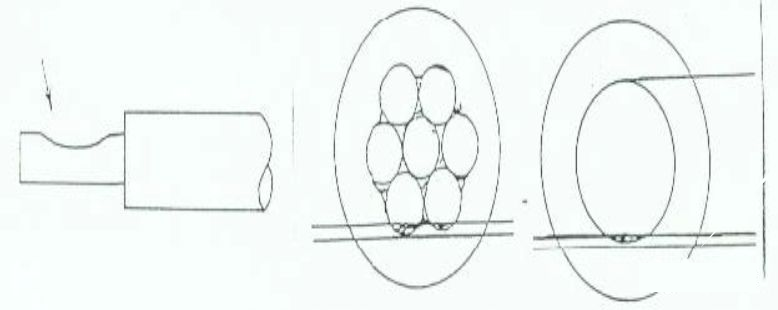

3).Wire Strands Cut Off

Definition:

Excessive cutting causes part of the wire to bounce off.

Possible Reasons:

1. The cutting bezel is poorly installed.

2. The central position of the conductor in the wire exceeds the standard.

Control Standard:

Wire strands cut off is not acceptable.

Basic Principles:

1. Affect the electrical conductivity.

2. Affect the crimping effect.

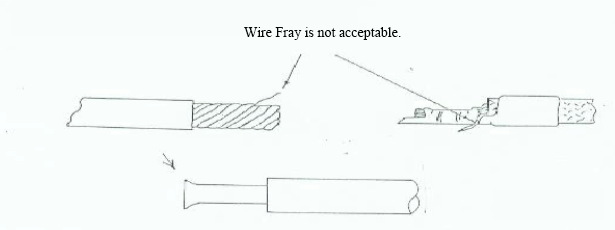

4).Wire Fray

Definition:

The wire fray refers to the metal shavings or rough cutting edges produced during the stripping of the wire.

Possible Reasons:

The cutting tool or blade is blunt.

Control Standard:

As long as the conductor terminal port after insulator stripping can be easily plugged into the PCB interface or cable interface, it is allowed.

Basic Principles:

Affect the plug-in process.

5).Poor Cutting of Insulator

Definition:

The cutting edge of the insulator is worn and damaged.

Possible Reasons:

1.The cutting bezel is poorly installed.

2.The cutting blade is blunt.

Control Standard:

If the stripping length of the insulator exceeds the standard, it will be rejected.

Basic Principles:

Bad crimping may be caused by poor insulator cutting.

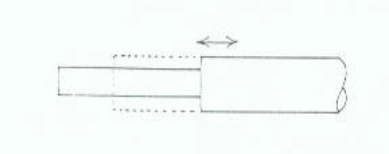

6).Insulator Relaxation

Definition:

The contact between the wire insulator and the conductor slides, and the contact is not close.

Possible Reasons:

The wire is of poor quality.

Control Standard:

The wires must meet the supplier’s tightening standards.

Basic Principles:

1.Insulator relaxation will affect the quality of insulator stripping length.

2.It is apt to shake in the process of soldering.

7).Wire Gap or Damage

Definition:

A defect or notch on an insulator or bare conductor when it is cut or crimped.

Insulation gap of wire is not acceptable.

Conductor gap of wire is not acceptable.

Possible Reasons:

The cutting bezel is poorly installed.

Control Standard:

Insulation gap of wire:

1.The gap in the insulator does not allow the conductor to be exposed, otherwise it will not be accepted.

2.The notched wire passes the “bending test”, and if the conductor is not exposed, then it is allowed.

Conductor gap of wire is not acceptable.

Basic Principles:

1.Gaps in insulators may cause short circuits.

2.The gap in the bare conductor can easily lead to the fracture of the wire.