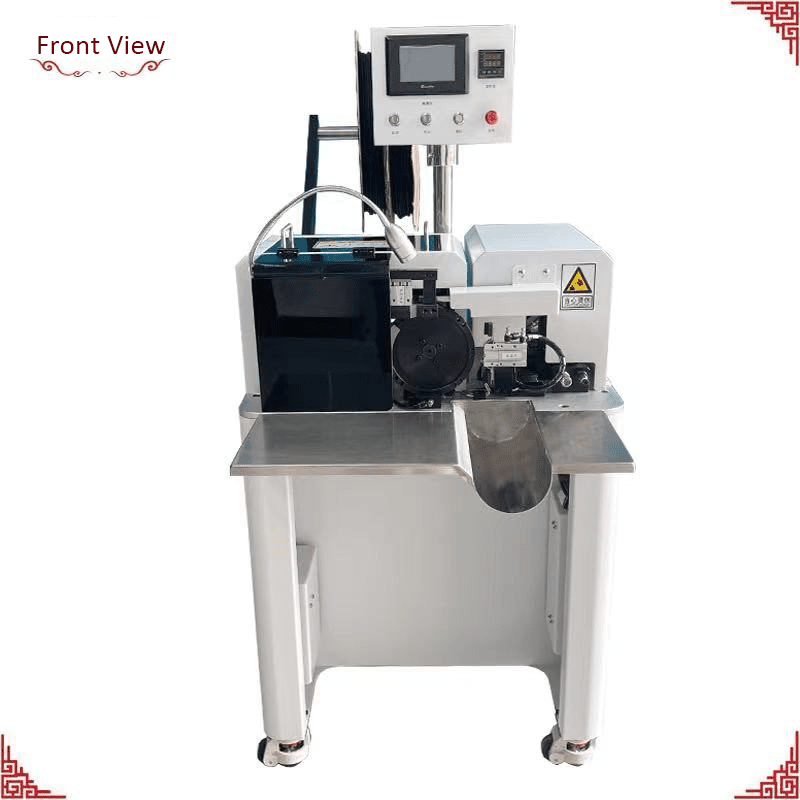

HH-210B Shrink Tube Cut, Insert and Heat Machine

Product Features

※ Industrial automation PLC, man-machine interface control, simple operation, stable work, high efficiency.

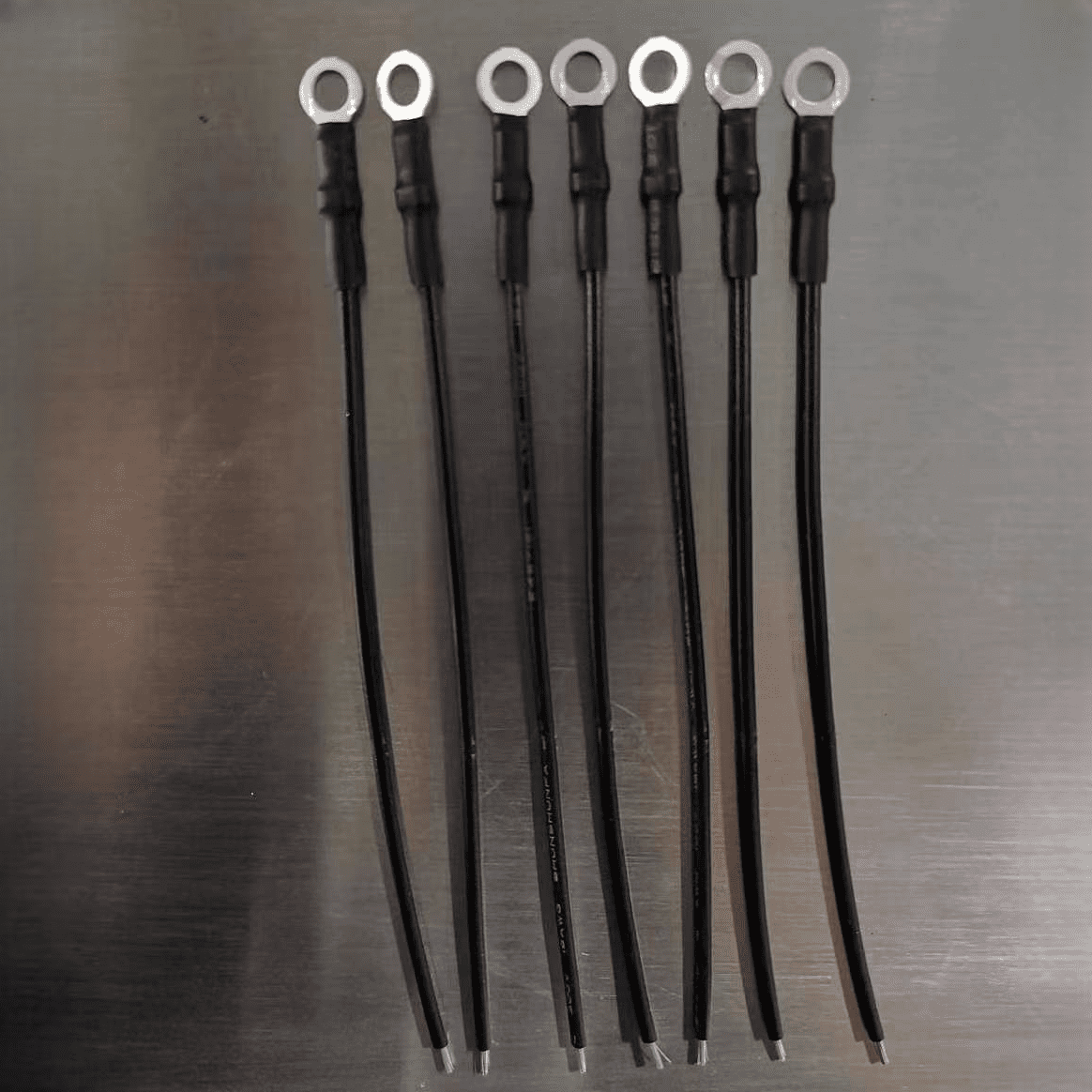

※ The heat-shrinkable tube is fed automatically, the heating length can be set, and the heating position can be adjusted by positioning device.

※ The production capacity can reach 700-2500 terminals per hour (depending on the manual speed).

※ The equipment is compatible, and a variety of cable assembly can be processed by changing rotating disc and fixtures.

※ Digital temperature control and abnormal monitoring of heating device. The heating device, when too low air pressure, is protected automatically to prolong the service life.

※ To prevent operator adjusting parameters wrongly, the system can be restored with one button click.

Operating Videos

HH-210A https://youtube.com/shorts/aOQXZoqzhmg 2 wires

HH-210A https://youtube.com/shorts/adsBfsk6rhM 3 inner cores simultaneously

HH-210A https://youtu.be/HoJYuWdMBo4 2-pin varistors

HH-210B https://youtube.com/shorts/qCEzTC61scE

HH-210B https://youtu.be/7t-0QVeJ7kA 2-pin cable

HH-210B https://youtube.com/shorts/jjnNcLxo6DU 2 wires

HH-210C https://youtube.com/shorts/gSXrsLUSTCI large cable assembly

Details About HH-210B Shrink Tube Cut, Insert and Heat Machine

Technical Parameters

| Model | HH-210 Shrinkable Tube Cut, Insert and Heat Machine |

| Power | 220V-AC,50/60HZ |

| Rated Power | 1350W |

| Display | 4.3 Inch Touch Screen TFT |

| Running time/cycle | 2.2 seconds |

| Control Mode | PLC/ Touch Screen |

| HST Range | 1.0mmΦ~6.5mmΦ(≥7.0mm to be done on HH-210C) |

| HST Processing Length | 4MM~50MM(customized rotating disc and fixtures) |

| Heating Temperature | 200℃~380℃(Adjust via the thermostat) |

| Air Supply | 0.55~0.65Mpa, clean and dry air |

| Cooling mode | Forced air cooling |

| Dimension | L 500mm*W 640mm*H 1300mm |

| Weight | 78KG |