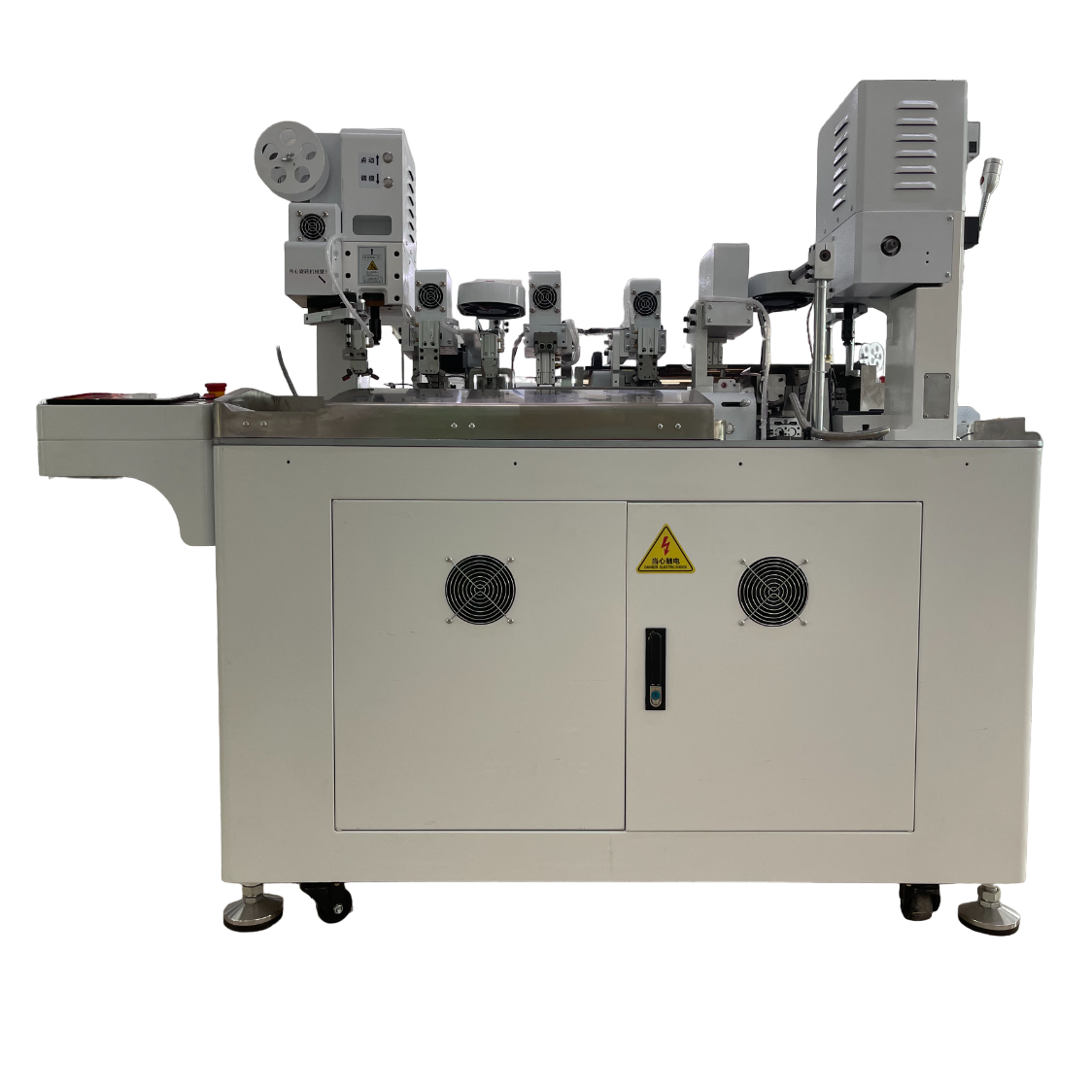

HH-682B Fully-automatic Dual Ends Terminal Crimp Machine(Stepping Version)

Product Description

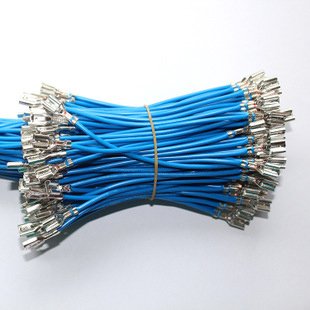

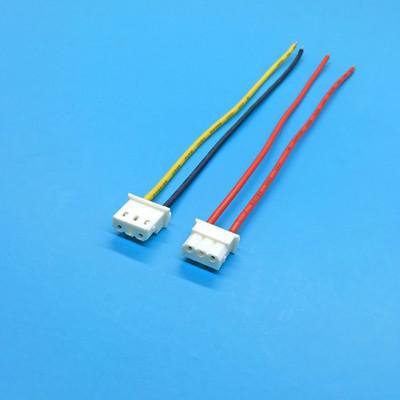

HH-682B adopts double ends terminal crimping mode to realize its functions of double ends terminal crimping. The transmission part of the machine adopts stepping motors and Taiwan guide rail and screw rod, etc., to make the machine durable, accurate, and efficient. The touch screen setting is adopted to realize the easy function conversion, which is simple and convenient.

Operating Video:

HH-682B https://youtu.be/jJyXACHJsWg

HH-682C https://youtu.be/y0ZSpH7D22Y

HH-682C https://youtu.be/zsUuis9CGso 0.6mm²+1.25 terminals

HH-682C https://youtu.be/64iZKsNz0A0 loose terminals and linked sheath terminals

Details About HH-682B Fully-automatic Dual Ends Terminal Crimp Machine(Stepping Version)

Product Features

※ The blades are adjusted by computer, no gasket is needed;

※ Half stripping can be realized at the back end of the cable;

※ The 5-inch WEINVIEW operation screen;

※ AIRTACpneumatic component;

※ The control system is the32-bit single-chip microcomputer;

※ Guiderail is from Japan THT, Taiwan HIWIN

※ Testing devices are from KEYENCE and OMRON.

Technical Parameters

| Machine Model | HH-682B Fully-automatic Double Ends Terminal Crimping Machine(Stepping Version) |

| Display Language | English |

| Max. Capacity | 4000 pieces/h/50mm-length |

| Wire Range | AWG#30~AWG#10 |

| Insulated wire Length | 40~9999mm |

| Cutting Precision | ﹤± (0.1+0.005*L), L= Cutting Length |

| Stripping Length | 0.1~10mm(longer striping length may be customized) |

| Crimping Capability | 2.0T per crimping station |

| Control Model | 32-bit single-chip microcomputer |

| Rated power | 1.5KW/h |

| Power & Air Supply | AC 220V, 50/60Hz, Single phase, 0.5Mpa |

| Dimension | 1060mm*800mm*1500mm |

| Weight | About 330Kg |

| Wire Types | AV, AVS, AVSS, UL |

| Functions | Wire cutting & stripping, terminal crimping, and the testing of wire lacking, wire over-straighten, stripping&crimping, and low air pressure. |