HH-688 Fully-automatic dual Ends Seal Insert & Terminal Crimp Machine

Product Description

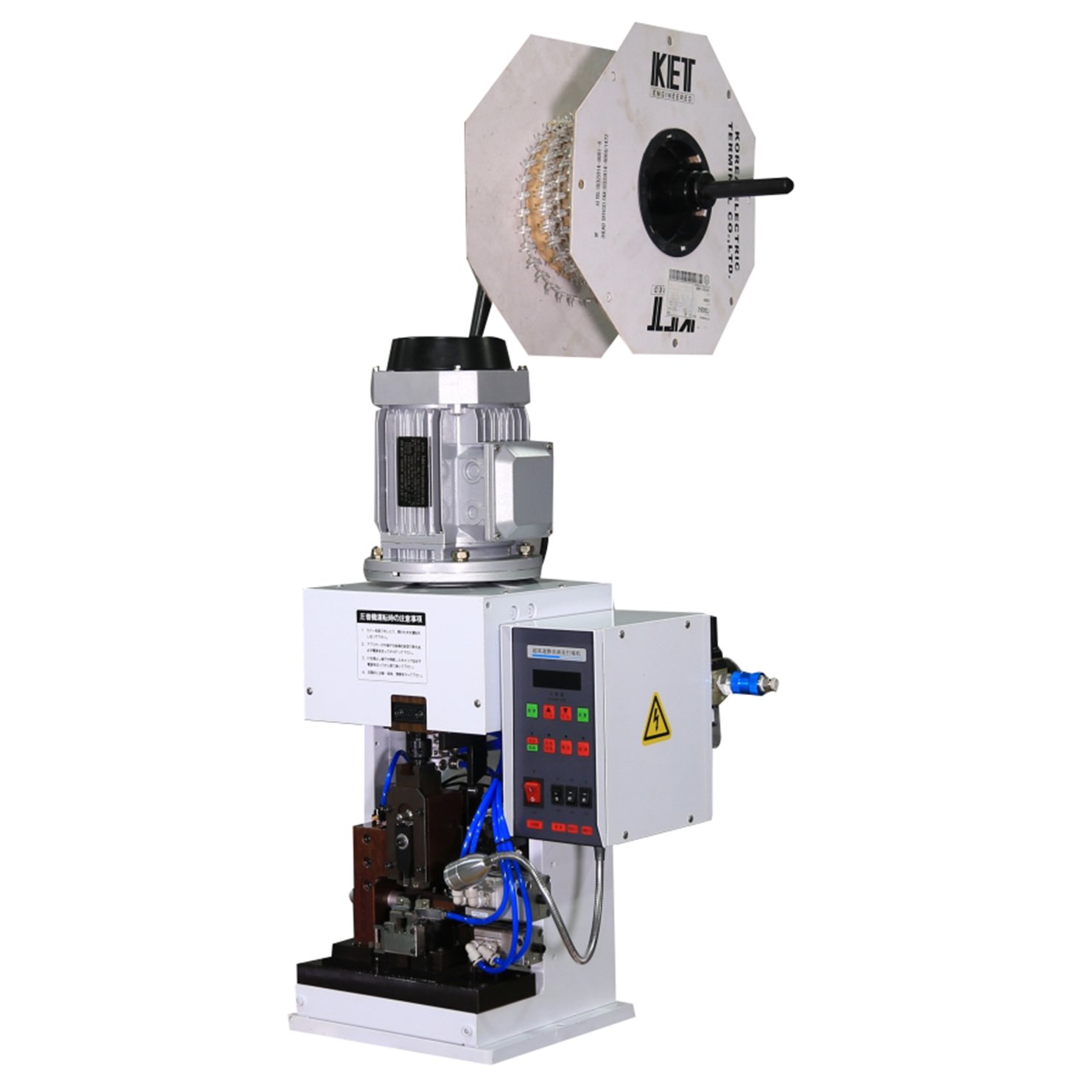

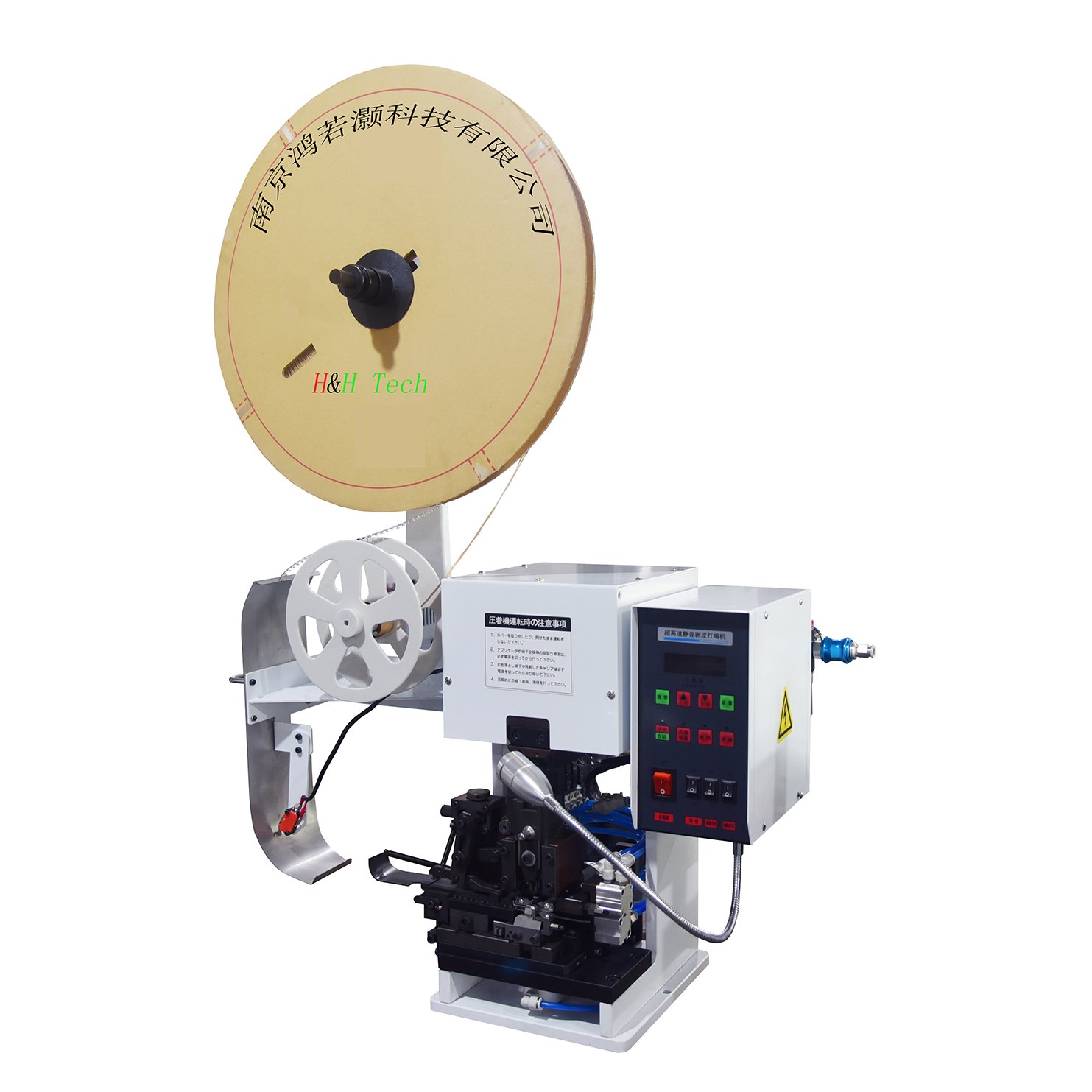

The high-precise automatic double-end seal inserting & terminal crimping machine adopts Mitsubishi servo motor & Mitsubishi control system, and ball screw drive, so that the positions of wire feeding, stripping, seal inserting and terminal crimping are very accurate, and the movement connection between them is smooth. Mechanical operating control is simple, convenient, and time-saving while debugging, as data adjustments of stripping length, cutting depth, and crimping position are all operated by the touch screen. The automatic detecting device can also effectively control the occurrence of defective products so that they can be found and dealt with in time. HH-688 is a safe, efficient, and precise processing machine that brings you safety, efficiency, and precision. (HH-688 can be customized according to requirements.)

Operating Video:

HH-688 https://youtu.be/Eg–1t9vMKM

Details About HH-688 Fully-automatic dual Ends Seal Insert & Terminal Crimp Machine

Product Features

※ Servo crimping is adopted;

※ Crimping stations can adopt applicators of Japanese, European, Pneumatic, etc.;

※ The seal inserting system with Japanese technology is adopted.

※ Equipped with crimping force monitor, CCD imaging system, etc.;

※ Equipped with a safety shield to protect the personnel.

Technical Parameters

| Machine Model | HH-688 Fully-automatic Double Ends Seal Inserting & Terminal Crimping Machine |

| Display Language | English |

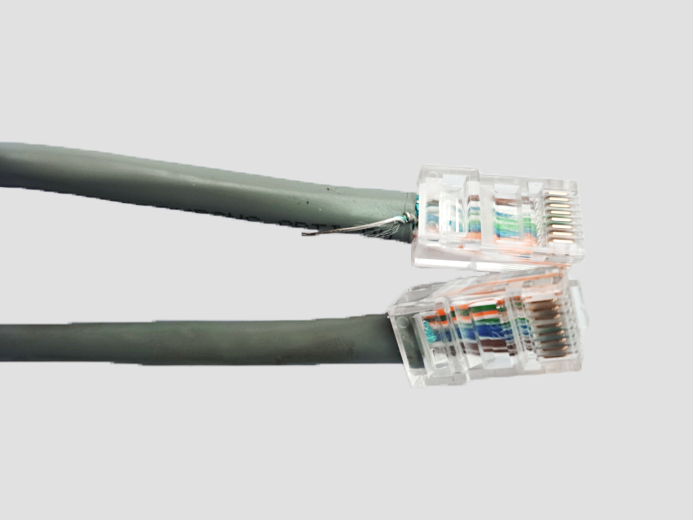

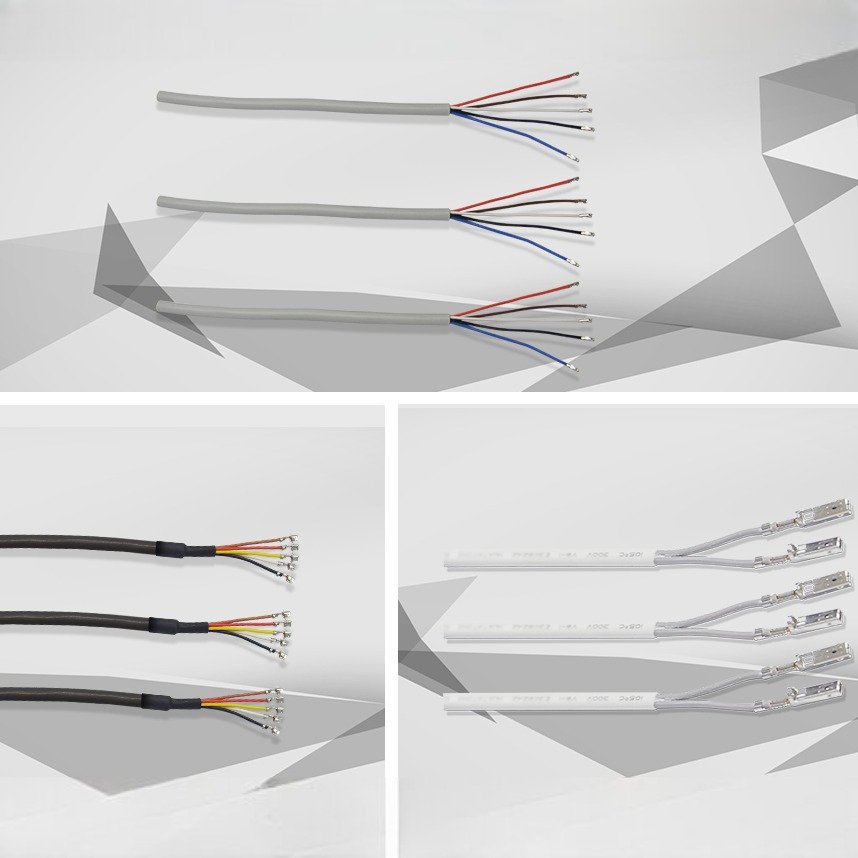

| Wire Range | 0.2~2.5mm² |

| Insulated wire Length | 35~9999mm |

| Cutting Precision | ﹤± (0.1+0.005*L), L= Cutting Length |

| Stripping Length | 0~15mm |

| Crimping Capability | 2.5T |

| Crimping Drive Mode | Servo Crimping |

| Power & Air Supply | AC 220V, 50/60Hz, 0.5Mpa |

| Dimension | 1200mm*1100mm*2300mm |

| Weight | About 525Kg |

| Wire Types | AV, AVS, AVSS, CAVUS, KV,KIV, UL |

| Functions | Wire cutting & stripping, terminal crimping and Seal inserting |

-2-1.jpg)