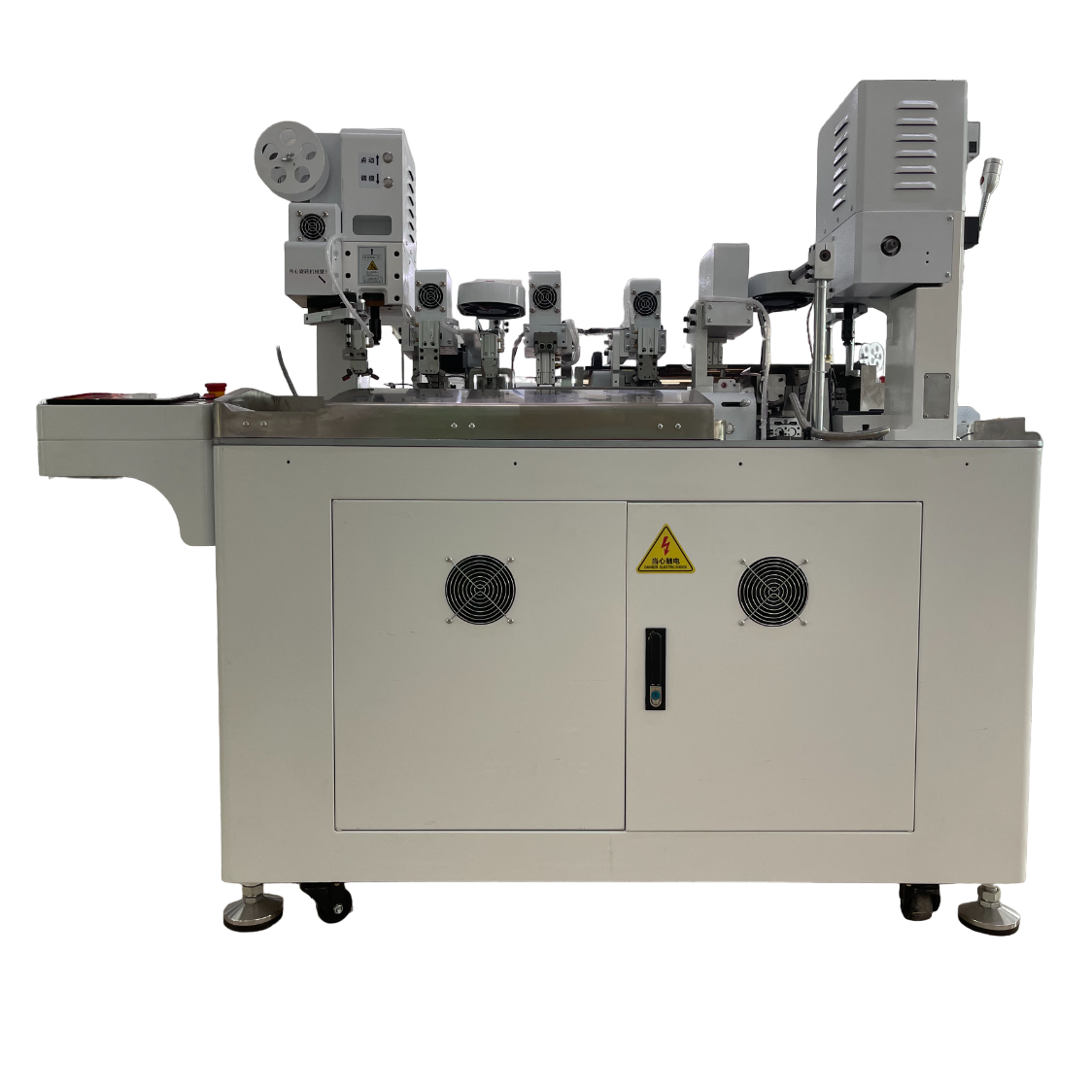

HH-680A Fully Automatic Dual Ends Terminal Crimp and HST Process Machine

Product Features

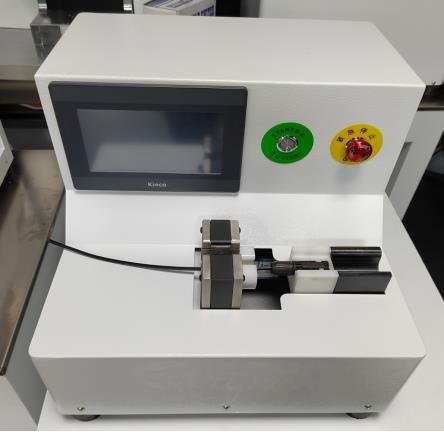

※ Exquisite and compact design, small footprint, computer touch screen with Chinese/English;

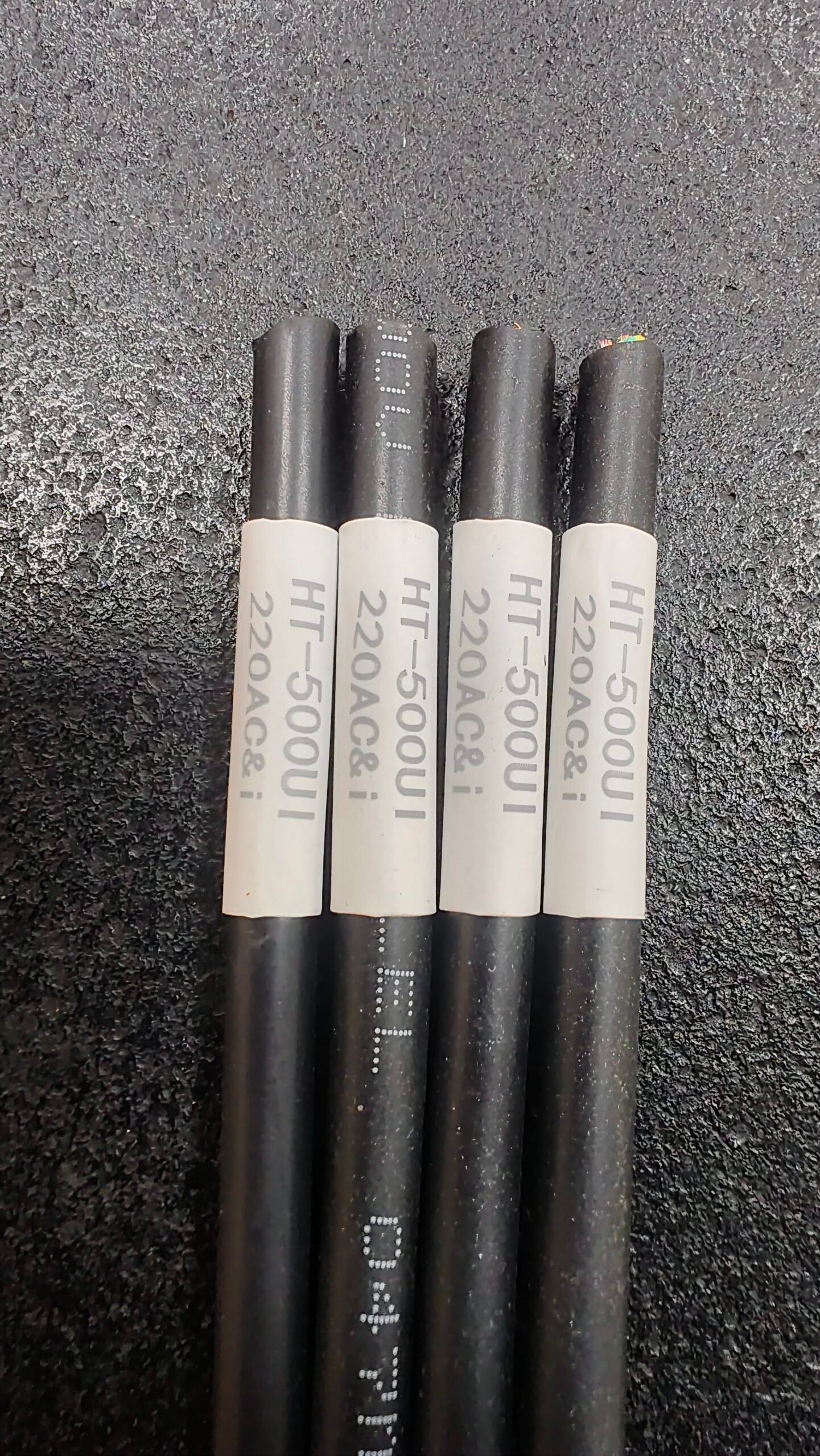

※ Dual ends crimped with terminals, while shrink tube is cutting, inserting on the cable and heating on both ends;

※ HH-680 can also be customized with functions of loose terminal crimping, sleeve inserting, wire soldering, copperbelt splicing, etc..

※ Both horizontal and vertical OTP crimping applicators can be used, and they can be quickly changed;

※ Wire cutting length, stripping length and terminal crimping depth are all numerically controlled by touch screen, which is easy to learn, understand and skillfully operate.

Operating Videos

HH-680A https://youtu.be/80zSzgonKiA terminal crimp &HST processing➕wire soldering

HH-680A https://youtube.com/shorts/_PoARI_A86g dual ring terminal crimp + hst process

HH-680C https://youtu.be/bVROqF-kPOo dual terminal crimp +hst process +copperbelt splice

HH-680B https://youtube.com/shorts/eYH3OHDUtko dual crimp+sleeve insert+hst process

Details About HH-680A Fully Automatic Dual Ends Terminal Crimp and HST Process Machine

Technical Parameters

| Machine Model | HH-680A Fully Automatic Dual Ends Terminal Crimping and HST Processing Machine |

| Display Language | English |

| Max. Capacity | 1700~2300 pieces/h/150mm-length |

| Wire Range | AWG#24~AWG#12 (0.3~4 mm²) |

| Insulated wire Length | 60~9999mm(conveyor is necessary if more than 800mm) |

| Cutting Precision | ﹤± (0.1+0.005*L), L= Cutting Length |

| Stripping Length | 0.1~15mm(longer striping length may be customzed) |

| HST size | Length of 15~35mm, diamater of 3mm~8mm |

| Crimping Capability | 2.0T |

| Rated power | 2.5KW/h |

| Power & Air Supply | AC 220V, 50/60Hz, 0.5~0.7Mpa |

| Dimension | 1700mm*850mm*1800mm (Main Body) |

| Weight | About 600Kg |

| Functions | Wire cutting & stripping, terminal crimping, shrink tube proceiing, sleeve inserting, wire soldering, copperbelt splicing, etc.. |

Related products

-

- Sale!

- Uncategorized

HH-75 Nut Tightening Machine

-

$1.00$0.00 - Add to Quote

-2-1.jpg)