HH-685A Multi-functional Dual Ends Terminal Crimp and Solder Machine

Product Description

HH-685Aadopts five-wire feeding and five-wire simultaneous processing mode to realize the functions of double-ended terminal crimping and single-end twisting & tinning. The transmission part of the machine adopts imported hardware such as Mitsubishi motor and Taiwan guide rail and screw rod, etc. And uses a high-speed single-board computer and another control system to make the machine durable, accurate, and efficient. The Taiwan touch screen setting is adopted to realize the easy function conversion, which is simple and convenient.

Operating Video:

HH-685A https://youtu.be/kxdaDu4J_l8

HH-685A https://youtu.be/QTjOs7T7TUA Flat/ribbon cable

HH-685A https://youtu.be/58sfFA33ebs 3 electronic wire

Details About HH-685A Multi-functional Dual Ends Terminal Crimp and Solder Machine

Product Features

※ Mitsubishi servo control is adopted in the transmission part of the motor, which is accurate and reliable;

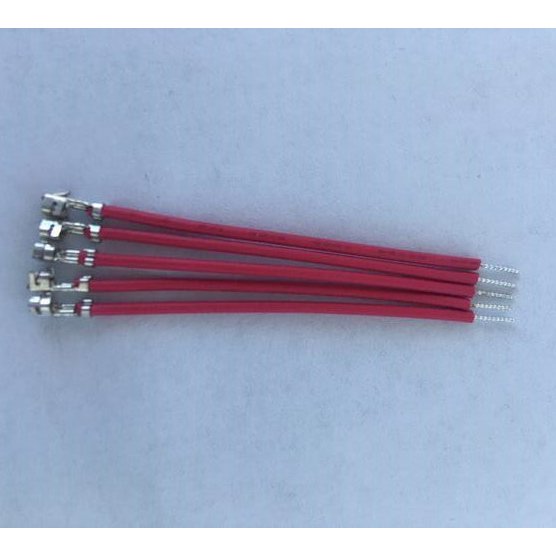

※ Realize the functions of double-end terminal crimping, and single-end terminal crimping & single-end wire twisting and tinning;

※ Higher efficiency and better reliability;

※ Equipped with belt conveying structure, which can straighten the processed wire.

Technical Parameters

| Machine Model | HH-685A Multi-functional Double Ends Terminal

Crimping and Tinning Machine |

| Display Language | English |

| Max. Capacity | 7000pcs/h(Single-end terminal crimping and tinning) |

| Wire Range | AWG#32~AWG#18 |

| Insulated wire Length | 35~950mm |

| Cutting Precision | ﹤± (0.1+0.005*L), L= Cutting Length |

| Stripping Length | A: 1~15mm; B: 1~8mm |

| Crimping Capability | 2.0T |

| Crimping Drive Mode | Frequency converter drive |

| Power & Air Supply | AC 220V, 50/60Hz, 0.5Mpa |

| Dimension | 2700mm*1050mm*1600mm |

| Weight | About 450Kg |

| Wire Types | AV, AVS, AVSS, CAVUS, KV,KIV, UL |

| Functions | Wire cutting & stripping, terminal crimping, and Wire twisting & tinning |